Aluminum heat sink and its types

Aluminum heat sink and its types

Heat sinks are generally made of metals; and, aluminum is the most common metal used in the heat sink.

We are aware of the fact that the thermal conductivity of each metal is different.

The thermal conductivity of metal is proportional to the heat transfer in heat sink.

Thus, if the thermal conductivity of the metal increases, then the heat-transferring capacity of the heat sink will also increase.

The thermal conductivity of aluminum is 235 W/mK; it is the cheapest and most lightweight metal.

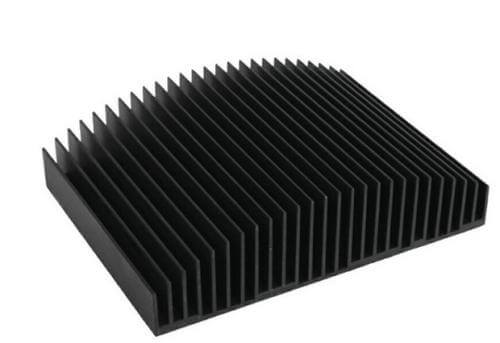

Aluminum heat sinks are also called as extruded heat sinks as they can be made using extrusion.

Aluminum heat sink and its types

The heat sinks are classified into different categories based on different criteria, according to the production process, can be classified as the following:

Stamped Heat Sinks

These are made of metals that are stamped to form a particular shape.

This stamp creates heat sinks whenever metal is moved through the stamping machine.

These are cheaper compared to extruded heat sinks

These are used for low-power applications and hence they are low in performance.

Machining Heat Sinks

These are manufactured by machining process; frequently gang saw is used for removing a block of material to make inter fins with precise spacing.

These are expensive as a lot of metal may go as wastage in the manufacturing process.

Bonded-Fin Heat Sinks

These are frequently used for physically large applications that require sensible performance like electric welding and DC-DC brick applications.

These are made by bonding individual fins of metal to the base of a heat sink.

This can be done in two methods namely thermal epoxy which is economical and the other is by brazing which is expensive.

Folded-Fin Heat Sinks

These folded-fin heat sinks have a large surface area and possess folded heat sink material, and hence, they have very high performance and very-high heat-flux density. In these sinks, the air is directed to flow directly into heat sinks through some kind of duct.

This makes the whole thing expensive as the cost of manufacturing and ducting is included in the overall cost of the sink.

Skived Heat Sinks

The skiving process is used for manufacturing these sinks, which involves making very fine blocks of metals generally copper.

Hence, these are called as skived heat sinks. These are medium to high-performing heat sinks.

Forged Heat Sinks

The metals like copper and aluminum are used to form heat sinks by using compressive forces.

This process is termed as forging process. Hence, they are named as forged heat sinks.

Single Fin Assembly Heat Sinks

These are lightweight and can be installed in tight spaces.

They also possess low to high-performing capability and can be used for many applications. But the major drawback is that they are a bit expensive.

Swaged Heat Sinks

Swaging is a cold working forging process but sometimes can be done even as hot working process in which the dimensions of an item are altered into a die.

These are inexpensive, medium performing and are limited in air-flow management.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.