Custom aluminum extrusions

Custom aluminum extrusion,precision custom aluminum extrusions

Custom aluminum extrusions

Custom aluminum extrusions

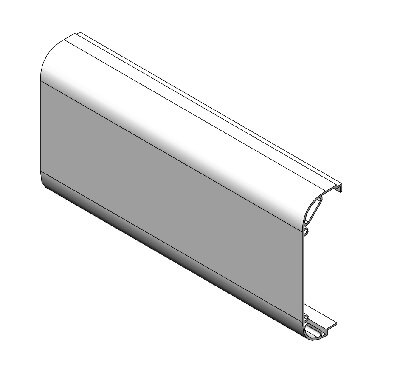

Custom aluminum extrusion is a manufacturing process that involves forcing aluminum billets through a specially designed die to create a profile with a specific shape.

Unlike standard aluminum extrusion, which uses pre-existing dies to produce standardized shapes, custom aluminum extrusion allows for the creation of unique profiles tailored to the specific needs of the application.

Custom aluminum extrusion is a versatile manufacturing process that enables the production of aluminum profiles with intricate shapes, complex geometries, and tight tolerances.

You name it and we build it.

Now see how it happens in Honstar for custom aluminum extrusions.

It’s your job to have ideas. It’s our job to make them happen.

The best aluminum extruder requires a true understanding of the end user’s needs.

Our working team, high-quality aluminum materials, automated production line and anodizing and powder-coated production equipment, and our fabrication workshop, all these can provide an ideal environment to develop precision custom aluminum extrusions and deliver what you need.

A custom die is designed and created with a cross-sectional profile that best suits your needs.

The material is shaped as it is pushed through the shaped opening in the die, taking on the same profile as the die opening.

Custom aluminum extrusions can be fabricated with holes and other features to benefit the manufacturing process.

A major benefit of this manufacturing process is that it can create complex designs that are uniform across the material length.

Custom aluminum extrusions can be created with a wide variety of aluminum grades, and designed and produced to close tolerances with a wide range of finishes.

Custom Aluminum Extrusion

Custom aluminum extrusions are shapes that are specifically designed for a particular application.

They are typically produced in smaller quantities than standard extrusions, which makes them more expensive.

However, custom extrusions offer several advantages over standard extrusions, including:

- Greater flexibility:

Custom extrusions can be made in any shape, size, or alloy.

This means that they can be designed to meet the specific needs of any application.

- Improved performance:

Custom extrusions can be designed to optimize strength, weight, and other performance characteristics.

- Reduced waste:

Custom extrusions can be designed to eliminate the need for secondary machining operations, which can reduce waste and save money.

Custom aluminum extrusions from Honstar Aluminum Products

Honstar provides custom aluminum extrusion design assistance to help you get your project off the ground.

We have built a reputation in extruding high-visual, tight tolerance, complex, thin-walled, lightweight, and precision aluminum extrusions

Honstar provides superior quality custom aluminum extrusions, fabrications and outstanding individualized customer service.

Honstar aluminum products house extensive standard-shaped die banks for customers to utilize quicker lead times.

Aluminum extrusions are just the beginning of what we do. We can supply a host of services from design assistance to customized packaging to make your aluminum extrusion experience smooth!

At Honstar Aluminum Products, you will experience personalized service, quality manufacturing, and satisfaction that take you beyond your highest expectations.

Benefits of Custom Aluminum Extrusion:

Design Flexibility: Custom aluminum extrusion offers unparalleled design flexibility, enabling the creation of complex shapes, intricate features, and tight tolerances that are not possible with standard extrusions.

Strength and Durability: Aluminum is a lightweight yet strong metal, and the extrusion process further enhances its strength-to-weight ratio. Custom aluminum extrusions can withstand significant loads and harsh conditions, making them ideal for demanding applications.

Corrosion Resistance: Aluminum is naturally resistant to corrosion, and custom aluminum extrusions can be treated with additional surface finishes to further enhance their resistance to weathering, chemicals, and other environmental factors.

Weight Reduction and Energy Efficiency: Aluminum’s lightweight nature contributes to weight reduction in products and structures, leading to improved fuel efficiency in transportation applications and reduced material costs in construction.

Sustainability and Recyclability: Aluminum is one of the most recyclable metals, and custom aluminum extrusions can be recycled repeatedly without losing their properties. This contributes to environmental sustainability and resource conservation.

Aesthetics and Appearance: Custom aluminum extrusions can be finished with various surface treatments, such as anodizing, powder coating, and brushing, to achieve a desired aesthetic. This allows for a range of visual appeals, from sleek and modern to classic and traditional.

Applications of Custom Aluminum Extrusion:

Custom aluminum extrusions are widely used in a diverse range of applications, including:

Architecture and Construction: Custom extrusions are used for window frames, doorframes, curtain walls, railings, and structural components.

Transportation: Custom extrusions are used for aircraft frames, automotive components, train carriages, and bicycle frames.

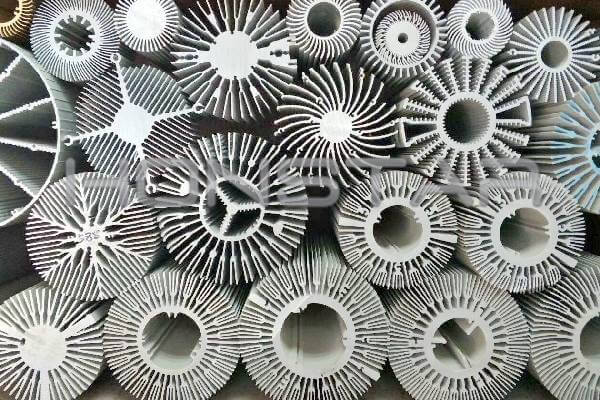

Electronics: Custom extrusions are used for heat sinks, enclosures, chassis, and structural components.

Industrial Machinery: Custom extrusions are used for conveyor frames, robot arms, machine guards, and tool handles.

Medical Equipment: Custom extrusions are used for wheelchair frames, crutches, medical devices, and surgical instruments.

Furniture and Equipment: Custom extrusions are used for furniture frames, table legs, drawer rails, decorative accents, and equipment housings.

Other Applications: Custom extrusions are also used in a variety of other applications, such as signage structures, lighting fixtures, and consumer products.

In summary, custom aluminum extrusion offers a versatile and cost-effective solution for creating unique aluminum profiles that meet specific design requirements and functional needs.

Its ability to combine strength, durability, aesthetics, and sustainability makes it a valuable material for a wide range of industries and applications.

There are several key reasons why custom aluminum extrusion is a popular choice for a wide range of applications:

Versatility:

Shape and Size: Aluminum extrusions can be created in an incredibly wide variety of shapes and sizes, limited only by the design’s complexity and the physical limitations of the extrusion press.

This makes them ideal for applications where standard shapes won’t suffice, allowing for precise customization to unique needs.

Finish and Color: Customization extends beyond just shape.

Aluminum extrusions can be anodized, painted, or powder coated in a vast array of colors and textures, further enhancing their visual appeal and functionality.

Strength and Lightweight:

Strength-to-Weight Ratio: Aluminum boasts a superb strength-to-weight ratio, making it an ideal choice for applications where both structural integrity and lightness are crucial.

This can lead to weight savings in products, leading to improved efficiency and performance.

Durability: Aluminum naturally forms a protective oxide layer on its surface, offering good resistance to corrosion and weathering.

This ensures long-lasting performance and reduces the need for frequent maintenance.

Cost-Effectiveness:

Material Efficiency: The extrusion process minimizes material waste compared to other fabrication methods, leading to cost savings.

Additionally, aluminum is readily available and relatively inexpensive, further enhancing its overall affordability.

Design Optimization: Custom extrusions can integrate multiple features into a single component, eliminating the need for separate parts and assembly costs.

This simplifies design, reduces production time, and lowers overall expenses.

Other Advantages:

Machinability: Aluminum is easily machined and welded, making it compatible with various finishing and joining techniques.

This allows for further customization and integration with other components.

Conductivity: Aluminum is a good conductor of heat and electricity, making it suitable for applications involving heat sinks, electrical enclosures, and other components requiring these properties.

Sustainability: Aluminum is highly recyclable, with over 70% of all ever-produced aluminum still in use today.

This makes it an environmentally friendly choice for businesses and consumers alike.

In summary, the popularity of custom aluminum extrusion stems from its exceptional versatility, strength-to-weight ratio, cost-effectiveness, and wide range of additional benefits.

Its ability to be tailored to specific needs makes it an ideal solution for engineers, designers, and manufacturers across various industries.

What is the design principle of custom aluminum extrusion?

To achieve this level of precision and design flexibility, it’s crucial to adhere to specific design principles that optimize the extrusion process and ensure the desired outcome.

Key Design Principles for Custom Aluminum Extrusion:

1. Simplicity and Symmetry: Aim for simple and symmetrical designs whenever possible.

This simplifies the extrusion process, reduces die complexity, and minimizes stress concentrations, leading to a more cost-effective and defect-free product.

2. Minimum Wall Thickness: Maintain sufficient wall thickness to support the intended load and provide the desired strength and stiffness.

However, avoid excessive wall thickness, as it increases weight and cost unnecessarily.

3. Balanced Web Thickness: For hollow profiles, ensure balanced web thickness to distribute the load evenly and prevent web buckling.

Excessive web thickness can also increase weight and cost, while insufficient thickness may compromise structural integrity.

4. Adequate Flange Width: For profiles with flanges, maintain sufficient flange width to provide the necessary bearing surface and support for the intended load.

However, minimize flange width to reduce weight and cost.

5. Generous Corner Radii: Employ generous corner radii to avoid stress concentrations and cracking.

Sharp corners can lead to premature failure, especially under load.

6. Realistic Tolerances: Specify realistic tolerances that balance the need for dimensional accuracy with manufacturability.

Tight tolerances may increase production costs and reduce yield, while excessively loose tolerances may compromise functional performance.

7. Modular Design: Consider a modular design approach, breaking down complex shapes into smaller, standardized modules.

This simplifies manufacturing, reduces tooling costs, and allows for easier assembly and maintenance.

8. Standardization Whenever Possible: Whenever feasible, utilize standard shapes and dimensions for components.

This reduces the need for custom tooling and leverages the cost-effectiveness of mass-produced standard extrusions.

9. Consider Post-Extrusion Processes: Anticipate any post-extrusion processes, such as machining, drilling, or anodizing, during the design phase.

This ensures that the extrusion geometry accommodates the required modifications without compromising its structural integrity or aesthetic appeal.

10. Consult with Experienced Extruders: Collaborate with experienced aluminum extruders early in the design process.

Their expertise can provide valuable insights into manufacturability, potential design limitations, and cost-effective solutions.

By adhering to these design principles, engineers and designers can create custom aluminum extrusions that are not only aesthetically pleasing but also functionally sound, cost-effective, and manufacturable.

Your premier choice for custom aluminum extrusion from China

Welcome to Foshan Honstar Aluminum Products Co., Ltd, your trusted China aluminum extrusion factory.

We are committed to providing unparalleled quality and expertise in the industry when it comes to custom aluminum extrusion from China.

With years of experience under our belt, we have established ourselves as a top choice for aluminum extrusion profiles supplier and exporter.

Key Takeaways:

- Foshan Honstar Aluminum Products Co., Ltd specializes in custom aluminum extrusion from China.

- Our company is experienced and committed to providing top-quality products and solutions.

- We are a trusted China aluminum extrusion factory with a proven track record of meeting specific requirements.

- Choosing us as your aluminum extrusion profiles supplier and exporter ensures high-quality standard aluminum extrusion products.

- Our company has a diverse range of aluminum extrusion profiles for various industrial needs.

Experience the reliability of our custom aluminum extrusion solutions.

At Foshan Honstar Aluminum Products Co., Ltd, we specialize in providing high-quality custom aluminum extrusion products and solutions.

Our dedication to precision and excellence has established us as a leading China aluminum extrusion factory, serving a wide range of industries.

Our custom aluminum extrusion solutions are tailored to meet the unique needs of our customers, ensuring reliability and satisfaction.

We offer a wide range of aluminum extrusion products and solutions that are designed to withstand the most demanding applications, providing durability and superior performance.

Our team of experts is committed to delivering customized aluminum extrusion product and solution, offering design and technical support to ensure optimal results.

We utilize advanced techniques and equipment to produce high-quality products, delivering consistent results that meet or exceed our customers’ expectations.

When you choose Foshan Honstar Aluminum Products Co., Ltd for your custom aluminum extrusion needs, you can be confident in the reliability and quality of our solutions.

Contact us today to discuss your specific requirements and discover how we can provide professional, tailored solutions.

A Trusted Aluminum Extrusion Profiles Supplier and Exporter

At Foshan Honstar Aluminum Products Co., Ltd, we are a China aluminum extrusion factory that takes pride in providing high-quality standard aluminum extrusion products and custom solutions to meet the unique needs of different industries.

We differentiate ourselves from other aluminum profiles suppliers by guaranteeing exceptional customer service, on-time delivery, and competitive pricing.

As a reputable aluminum extrusion profiles supplier and exporter, we ensure that our products meet international standards and undergo rigorous quality control measures at every stage of production.

From raw material selection to packaging and shipping, we strive to ensure that our customers receive only the best.

Whether you require standard aluminum extrusion profiles or custom solutions, we have the expertise and manufacturing capabilities to exceed your expectations.

Our range of products includes a wide variety of shapes, sizes, and finishes, providing you with the flexibility to choose the perfect aluminum profile for your project requirements.

Our dedication to excellence has earned us a reputation as a reliable aluminum profiles supplier that customers can trust.

When you partner with us, you can expect outstanding customer service, superior quality products, and competitive pricing that will help you realize your project goals.

High-quality standard aluminum extrusion from China

At Foshan Honstar Aluminum Products Co., Ltd, we take pride in delivering top-notch aluminum extrusion solutions to meet the unique needs of different industries.

Our range of standard aluminum extrusion products is no exception.

We adhere to the highest quality standards in all our manufacturing processes, ensuring that our customers receive only the best.

Our aluminum extrusion is carefully crafted using advanced techniques and equipment, and we go to great lengths to maintain our reputation as a trusted supplier and exporter of aluminum extrusion profiles.

Our standard aluminum extrusion products come in a range of shapes, sizes, and finishes, providing versatility and customization options for our customers. Whether you require a specific size or shape, or you need a unique finish, we have got you covered.

As a China aluminum extrusion factory, we prioritize quality control and customer satisfaction.

Our commitment to delivering high-quality standard aluminum extrusion products has made us a leading aluminum extrusion manufacturer in China.

If you are looking to source high-quality standard aluminum extrusion from China, look no further than Foshan Honstar Aluminum Products Co., Ltd.

We are your one-stop shop for all your aluminum extrusion needs.

Our Manufacturing Process for Custom Aluminum Extrusion

At Foshan Honstar Aluminum Products Co., Ltd, we pride ourselves on our advanced manufacturing process for custom aluminum extrusion.

As an aluminum extruder from China, we utilize cutting-edge technology, high-grade materials, and skilled professionals to provide our customers with unparalleled quality products.

Our process starts with a thorough analysis of our customer’s needs, ensuring that we create customized solutions that meet their exact specifications.

We use 3D modeling software to design and simulate our extrusion dies, ensuring optimal material usage and minimizing waste.

Once the design is finalized, we execute it using our state-of-the-art extrusion machinery, which is capable of producing complex shapes and profiles with tight tolerances.

Our extrusion process is carefully monitored to ensure that we maintain consistent quality across all of our products.

We then engage in a range of secondary operations, including cutting, drilling, tapping, and finishing, to deliver fully customized solutions that meet our customer’s unique requirements.

We’re committed to providing our customers with the highest quality products, and our thorough quality control measures ensure that each product is thoroughly inspected before it leaves our facility.

Choose Foshan Honstar Aluminum Products Co., Ltd for all your custom aluminum extrusion needs.

We’re the premier aluminum extrusion profiles supplier and exporter, and we’re committed to providing reliable, professional solutions to meet your exact specifications.

Explore Our Diverse Range of Aluminum Extrusion Profiles

At Foshan Honstar Aluminum Products Co., Ltd, we are your one-stop shop for all your aluminum extrusion needs.

As a leading China aluminum extrusion factory, we offer a wide range of aluminum extrusion profiles that are suitable for various applications.

Our aluminum profiles are available in different shapes, sizes, and finishes to meet your specific requirements.

From basic shapes such as round, square, and rectangular to more complex profiles, we have got you covered.

Our extrusion profiles have a high structural integrity and are engineered to meet the highest quality standards.

We use advanced manufacturing techniques and equipment to ensure that our products meet your expectations.

Whether you need profiles for windows, doors, curtain walls, or any other application, we have a solution that will meet your needs.

Our experienced team of engineers and technicians can also work with you to develop custom profiles that are tailored to your unique requirements.

As a trusted aluminum extrusion profiles supplier and exporter, we take pride in our commitment to customer satisfaction.

We prioritize quality control and timely delivery of our products to ensure that our customers get the best value for their money.

Choose a reliable aluminum extrusion manufacturer from China.

At Foshan Honstar Aluminum Products Co., Ltd, we take pride in our position as a leading aluminum extrusion manufacturer from China.

With years of experience in the industry, we have established ourselves as a reliable supplier and exporter of aluminum extrusion profiles.

We understand the importance of delivering high-quality products to our customers, and we strive to uphold our commitment to quality control, customer satisfaction, and on-time delivery.

Our state-of-the-art manufacturing facilities and advanced techniques enable us to produce custom aluminum extrusion solutions that meet the unique needs of different industries.

As a China aluminum extrusion factory, we offer a wide range of extrusion profiles in various shapes, sizes, and finishes.

Our products are tailored to meet the specific requirements of our customers, and we take pride in providing professional solutions to our clients.

At Foshan Honstar Aluminum Products Co., Ltd, we value our customers and their trust in our services.

Our team of experts is dedicated to providing unparalleled quality and reliable solutions, making us the top choice for all your aluminum extrusion needs.

Meeting your industrial needs with custom aluminum extrusion.

At Foshan Honstar Aluminum Products Co., Ltd, we understand that your business requires tailored solutions to meet unique industrial needs.

That’s why we provide custom aluminum extrusion products and solutions that are designed to address your specific requirements.

Our extensive experience in the aluminum extrusion industry has given us a deep understanding of the technical aspects and practical applications of aluminum extrusion products and solutions, allowing us to deliver exceptional services.

We work closely with our customers to ensure that we provide the ideal solution for their industrial needs.

| Our custom aluminum extrusion solutions. | Benefits to your business. |

| Designing and producing custom aluminum extrusion profiles to your specifications. | Optimized products that meet your specific industrial needs. |

| Providing technical assistance and support for your aluminum extrusion project from beginning to end. | Assured quality control and on-time delivery, with no compromise on safety. |

| Providing a range of surface treatment options, including anodizing, powder coating, and electrophoresis, to improve durability and appearance. | Increase product longevity and enhance the appearance of your products. |

Our commitment to quality control, customer satisfaction, and on-time delivery sets us apart as an industry leader.

We strive to provide professional solutions that are unparalleled in the industry.

- Professional consultation and support throughout the process.

- Customized solutions to meet your specific requirements.

- Exceptional customer service, with a focus on your satisfaction.

Choose Foshan Honstar Aluminum Products Co., Ltd for your aluminum extrusion product and solution needs, and experience the difference that quality and expertise can make.

Conclusion

At Foshan Honstar Aluminum Products Co., Ltd, we are committed to providing our clients with the best custom aluminum extrusion solutions from China.

As a top aluminum extrusion profiles supplier and exporter, our focus is to meet and exceed our customer’s expectations by delivering high-quality standard aluminum extrusion products and solutions for their specific needs.

Our extensive experience and commitment to excellence in design, manufacturing, and customer service make us a trusted choice for those seeking a reliable aluminum extrusion manufacturer from China.

We pride ourselves in delivering custom-made and standard aluminum extrusion profiles for various applications, meeting the unique needs of different industries.

Explore our diverse range of aluminum extrusion profiles, and experience the reliability of our custom aluminum extrusion solutions. For more information about our products and services, please contact us today.

How Aluminum Extrusion Enhances Product Design and Functionality

Aluminum extrusions are made by extruding metal under high pressure until it forms a certain shape.

The finished product can then be used for manufacturing, depending on the needs of the customer.

The extrusion process involves using a high-pressure press that forces a metal billet through an outlet, called a die, which is smaller and/or a differently-shaped cross-section that matches the desired shape of the bar or extruded shape required.

A nearly unlimited number of cross-sections can be produced using the extrusion method.

The resulting aluminum profile can be as long as is necessary but for handling and trucking purposes the standard length is 6 meters long.

In some cases, where small parts are made from the shape, the aluminum profile is cut into shorter lengths.

More than any other metal-forming process, the extrusion process creates various mechanical properties that may be required in the final part being produced.

The process produces an elongated grain structure that increases the raw material’s mechanical strength.

This metal is very easy to work and holds up well over the years, which is perhaps why it is so popular.

Plus, aluminum extrusions are easily customizable, so you can create them to the exact shape you need to complete your project with ease.

1. Complex and adaptable

The aluminum extrusion process involves 4Cr5MoSiV1 (US temper H13) alloy steel dies that determine the size and shape of the finished shape.

The purpose of the mold is to shape the heated aluminum billet into the desired shape.

There are a variety of options when it comes to the shape and size of your die extrusion to get the results you want.

You can use hollow or solid die in the extrusion process.

Solid dies produce extrusions without any hollow areas.

It is a one-piece simple mold similar to a template.

Hollow molds are shaped with one or more cavities.

It’s more complex than a solid, with two or more openings in a mold that join together to create an inner and outer shape that essentially flow together into a weld as it exits the mold.

Extruded aluminum product development allows for the use of various design features to meet the requirements of the application.

Complex shapes such as groves can be formed, in windows for example, to improve the design.

Aluminum extrusions offer designers the flexibility to achieve almost any desired design.

The fact that you can create any number of extruded aluminum shapes means the product is highly adaptable and can be used in a variety of different situations.

Before starting your project, you should note that you can buy aluminum extrusions not only in a variety of geometries, but also in tubes, flat bars, rod and angle products, etc.

No matter what type of project you’re working on, you can create custom aluminum extrusions in the shape you need to get the job done.

2. Extrudability and cost-effective

Aluminum is truly the metal of modern life.

As Aluminum is naturally soft and lightweight.

Aluminum can be extruded into a variety of different shapes for different applications.

As Aluminum’s extrudability leads to low tooling costs.

Since fewer parts need to be designed, fabrication is reduced and assembly is simplified, so aluminum will be cost-effective for your project.

3. Multiple surface finishes

Due to the naturally occurring oxide film that exists in aluminum and aluminum profiles, these profiles can receive a variety of surface finishes including anodizing, powder coating, fluorocarbon painting, electrophoresis coating, wood grain effect, bright dipping anodizing, brushing, polishing, shot blasting, hammer pinned, etc., which can easily be applied to further enhance its non-corrosive properties.

It can become suitable for even extreme environments.

4. Application in a wide range of industries

Due to the variety of aluminum profile designs, aluminum profile manufacturers offering this service can ensure their customers get what they need.

A wide variety of industries benefit from aluminum extrusion products, including electronics, agriculture, transportation, construction, military and defense, exercise and sports equipment, medical, robotics, and general machinery.

Aluminum profiles are also widely used in the automotive industry.

Because aluminum is both lightweight and strong, it can be used in place of heavier steel or other metals.

Innovative applications for aluminum are all around us.

The car you drive to work most likely has an aluminum hood and other lightweight parts to drive fuel efficiency.

Your house or office building likely uses aluminum windows and doors or maybe even a cool roof to improve insulation and decrease heating and cooling bills.

That airplane you fly in for summer vacation or that latest business trip would literally not be possible without lightweight aluminum as a key component.

Increasingly, even the high-tech gadgets you use to keep in touch with friends and family make use of sleek, attractive aluminum casings.

5. Economic and environmental protection

Those who don’t want to spend too much on building materials may want to talk to an aluminum extrusion supplier, as aluminum can be very affordable, especially when you consider its properties.

Perhaps one of the reasons its price is attractive is that it is the most abundant metal on earth.

Additionally, tooling costs for custom aluminum extrusion can often be recouped through weight and manufacturing savings in a single production run.

Aluminum is also easily recycled, which makes it more environmentally friendly than many other metals.

If you need to replace aluminum extrusions from your job site, you’re sure to find someone willing to recycle it.

6. Longer service life

In general, custom aluminum extrusions last longer than products made of plastic, steel, or other metals.

This is mainly because aluminum is very strong, especially for its weight, and is resistant to corrosion.

You’ll also find that aluminum extrusions can withstand high and low temperatures, which makes them useful in almost any environment.

Those who put their trust in aluminum extrusions are rarely disappointed with the end result, as it is a metal that pays for itself no matter what.

7. Machining ability and Lightweight

Can be made with different mechanical finishes and different machining works, such as cutting, punching, drilling, notching, bending, milling, tapping, welding, CNC machining, etc., which can meet the project demand.

Aluminum has an even higher strength-to-weight ratio than steel, and its weight is only one-third the weight of steel.

Not it is a big attribution to the Auto Industry.

This makes it easier to handle and less expensive to ship.

Aluminum profiles are also widely used in the automotive industry.

Because aluminum is both light and strong, it can be used in place of heavier steel or other metals.

This makes cars, trucks, SUVs and lighter, more energy-efficient to run and less expensive.

8. Excellent conductor of heat and cold

Extruded aluminum profiles have many advantages over other metals. Aluminum profiles are not only strong and lightweight, they are also excellent conductors of cold and heat.

Therefore, aluminum extrusions in the shape of heat sinks are a great alternative to using copper to dissipate heat.

From the analysis and comparison, aluminum heat sink is the best choice for heat sink material.

Whether it is energy-saving, materials, decoration, price, weight and other aspects are dominant.

The aluminum heat sink is widely used in the fields of machinery, automobiles, wind power generation, construction machinery, air compressors, railway locomotives and household appliances because of its superior performance.

9. Non-magnetic

Apart from all the advantages mentioned above, custom aluminum extrusions are also non-magnetic.

This feature enables its use in high-voltage applications.

This is why these extrusions are widely used by electronics and computer manufacturers.

Additionally, they are spark-resistant, which makes them safe for use in applications involving flammable materials.

With so many benefits to using aluminum extrusions, it is important to utilize the best option for your application.

How much does it cost to open mold for custom aluminum extrusion?

Aluminum extrusion, one process by which aluminum billet is forced into the tailor-made die and results in a constant cross section that utilizes all the properties of the metal.

Mold opening for custom aluminum extrusion is to customize the mold according to the needs of the customers, and then make extrusion and stretching of aluminum profile, also known as non-standard aluminum profile customization.

It is a way of business that is customized to meet the individual needs of the customers.

When the standard and public aluminum profiles on the market cannot meet the requirements of the customers, the mold of custom aluminum extrusion needs to be cut at this time.

Then some people will ask, since it is personalized customization, is it all more expensive for customization?

How much does it usually cost to open a new mold for custom aluminum extrusion?

It is necessary to use the mold for extruded aluminum profiles, and the cost of cutting molds is also a large cost, especially when many sets of molds need to be cut, the cost will inevitably rise.

Therefore, on the issue of mold opening, first, check whether it is necessary to cut new molds.

Honstar Aluminum Products carries a large inventory of aluminum extrusion molds in its 20-year production history, which are used in doors and windows, curtain walls, railings and other building profiles, as well as T slots, standard aluminum profiles and floor covering aluminum profiles.

First of all, we will match and query in the company’s internal system according to the drawings provided by the customer.

If it can be matched and it is a public mold, there is no need to cut the mold and save the mold cost for the customer.

If it is really necessary to cut a mold, the technical department of Honstar Aluminum Products will evaluate the difficulty of the drawings provided by the customer and also need to calculate the cost of the mold according to the size of the aluminum extrusion and the production extrusion press capacity.

The larger the model, the more complex the shape, and of course the higher the cost.

Of course, for Honstar Aluminum Products Co., Ltd, the mold cost can be refunded, when the customer uses the mold of custom aluminum extrusion to produce a certain quantity of aluminum extrusion, the mold cost will be refunded.

The mold cost is also a large expenditure, and it should also be included in the procurement budget.

The cost of aluminum extrusion mold is quite cheap compared with the cost of die-casting aluminum mold.

In general, one set of mold for custom aluminum extrusion costs hundreds to thousands of US dollars, and a small mold for custom aluminum extrusion even costs less than one hundred US dollars.

There is no standard for the price of mold for custom aluminum extrusion, and the price of the mold ranges from a few hundred to thousands of US dollars.

The specific price depends on the cross-sectional size of the mold and the difficulty of the size structure.

Generally, a mold with a small cross-section and a simple structure costs only hundreds of US dollars.

However, the section of the aluminum profile is large and the structure is complex, and the price of the mold with higher technical requirements is relatively high.

The parameters of mold-opening for custom aluminum extrusion, including aluminum profile size, mechanical properties, and morphological structure will affect the cost of mold-opening.

Therefore, for the specific quotation of mold opening, you can check it with Honstar Aluminum Products here, and we are glad to offer their suggestion and make quotations according to the actual situation.

Here are 3 factors related to the cost of mold for custom aluminum extrusion

1. Cross section

For custom aluminum extrusion, it is generally an extrusion process, so the opened mold is also an extrusion die.

The cost of the extrusion die is determined by the aspect ratio of the section of the aluminum profile, which means that the larger the section, the higher the die cost.

2. Mold machining process

The cost of mold of custom aluminum profile is also related to the machining process used in the production.

Some use fast-moving wire cutting, which is relatively cheaper, and some have high surface requirements, and it is more expensive to use slow-moving wire cutting, which is also a factor related to cost.

3. Type of mold

Another factor is that the type of mold determines its cost.

The mold is divided into two types: the flat mold and the porthole mold.

The flat mold is relatively cheaper.

The cost of the porthole die is more expensive because it is considered that the cavity extrusion profile is composed of two modules: the mandrel and the die container.

FAQ

What makes Foshan Honstar Aluminum Products Co., Ltd the top choice for custom aluminum extrusion from China?

We have extensive experience and expertise in the industry, ensuring unparalleled quality and customer satisfaction.

What types of custom aluminum extrusion solutions does Foshan Honstar Aluminum Products Co., Ltd offer?

We offer reliable and tailored solutions to meet the unique needs of different industries.

How can Foshan Honstar Aluminum Products Co., Ltd be trusted as a supplier and exporter of aluminum extrusion profiles?

We are committed to delivering high-quality products and meeting the specific requirements of our customers, making us a trusted choice in the industry.

What are the benefits of choosing standard aluminum extrusion from Foshan Honstar Aluminum Products Co., Ltd?

Our standard aluminum extrusion products adhere to high-quality standards and offer numerous advantages, providing reliable solutions for various applications.

What is Foshan Honstar Aluminum Products Co., Ltd’s manufacturing process for custom aluminum extrusion?

We utilize advanced techniques and equipment as an aluminum extruder from China, ensuring precision and expertise in our manufacturing process.

What range of aluminum extrusion profiles does Foshan Honstar Aluminum Products Co., Ltd offer?

We provide a diverse range of aluminum extrusion profiles with various shapes, sizes, and finishes, offering versatility and customization options for our customers.

Why should I choose Foshan Honstar Aluminum Products Co., Ltd as my aluminum extrusion manufacturer from China?

We are a reliable manufacturer committed to quality control, customer satisfaction, and on-time delivery, making us a trustworthy partner for your extrusion needs.

How do Foshan Honstar Aluminum Products Co., Ltd’s custom aluminum extrusion solutions meet industrial needs?

Our custom aluminum extrusion products and solutions cater to the specific needs of different industries, offering various applications and advantages, ensuring superior performance.

How can I get in touch with Foshan Honstar Aluminum Products Co., Ltd for my aluminum extrusion needs?

For any inquiries or to discuss your requirements, please contact us at [www.alu4alu.com, Email: sales@alu4all.com].

We are ready to provide professional solutions and unparalleled quality for your custom aluminum extrusion needs.