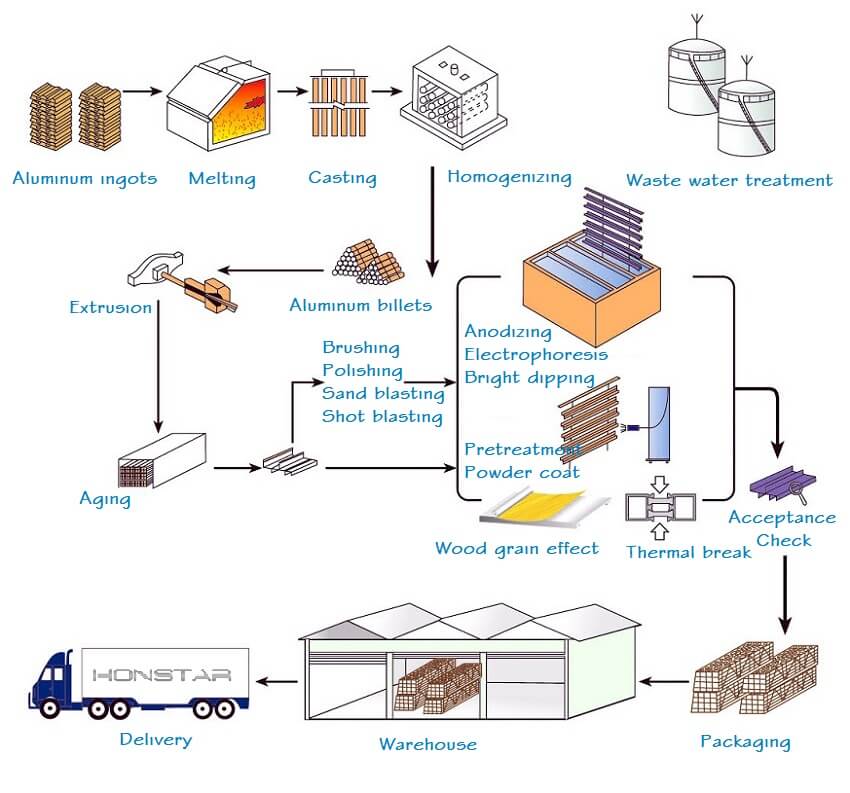

Our production process

Check our production processes and see how it happen in our factory for your products. From raw materials to delivery, we take the quality as our life.

No accept NG product, No produce NG product, No pass NG product.

Melting

The main raw material AL99.70 or higher quality aluminum ingots (GB / T1196),add Aluminum-Silicon alloy ingots and magnesium ingots for heating and melting, the melting temperature is 730 ℃ ~ 750 ℃, stirring, refining, slagging, etc.

Casting

Adopt the same level of hot top casting process and use different molds to produce aluminum billets with different diameters.

Homogenizing

Adopt 575 ℃ for 6 hours rapid cooling.

Extrusion

The aluminum billets are heated to about 450 ° C, using extrusion die, extruding various profiles with an extrusion machine, and quickly air-cooled or water-cooled, straightened, sawed and loaded them in the frame.

Aging

Adopt 190 ℃ ~ 195 ℃ for about 3.5 hours, and then use the forced air cooling process.

Anodizing

The aluminum profile substrate is used as the anode and placed in the electrolyte to energize. The anode generates oxygen atoms and oxygen atoms have strong oxidizability. A layer of Al2O3 protective layer with excellent performance is formed on the surface of the aluminum substrate. Metal ions (nickel ions, stannous ions) are filled into the Al2O3 protective layer, so that the anodizing film shows different colors.

Sealing

Using Ni2 +, F- cold sealing process.

Powder coating

Mill finish aluminum profile material is pre-treated by chromizing and powdered by electrostatic spraying. Curing: Bake the coated aluminum profile at 200 ° C for 10 minutes.