Anodizing, one kind of popular finish for aluminum profile

Anodizing, one kind of popular finish for aluminum profile

What is anodizing?

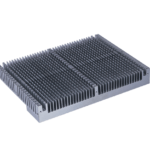

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

The anodic oxide structure originates from the aluminum substrate and is composed entirely of aluminum oxide.

This aluminum oxide is not applied to the surface like paint or plating but is fully integrated with the underlying aluminum substrate, so it cannot chip or peel.

It has a highly ordered, porous structure that allows for secondary processes such as coloring and sealing.

Anodizing is accomplished by immersing the aluminum in an acid electrolyte bath and passing an electric current through the medium.

A cathode is mounted to the inside of the anodizing tank; the aluminum acts as an anode, so that oxygen ions are released from the electrolyte to combine with the aluminum atoms at the surface of the part being anodized.

Anodizing is, therefore, a matter of highly controlled oxidation—the enhancement of a naturally occurring phenomenon.

Anodizing is a simple electrochemical process developed more than 75 years ago that forms a protective coating of aluminum oxide on the surface of aluminum.

The lifetime of the finish is proportional to the thickness of the anodic coating applied.

Aluminum oxide is a hard, durable, weather-resistant substance that protects the base metal.

The coating may be colored by dyeing or may exhibit bronze tones through diffraction phenomena produced by the coating.

The coating grows from the base aluminum metal by this electrochemical process.

The coating is integral to the metal and cannot peel or flake.

The structure of the coating is many small hexagonal pores, which are filled with a “seal” that hydrolyzes these pores to fill them with inert aluminum oxide.

Advantages of the anodizing

1. In general anodizing is less expensive than painting with the exception of coil-painted products.

2. Anodizing is harder than PVDF. Anodizing is better for aluminum in high-traffic areas where the coating is subject to physical abuse and abrasive cleaners.

3. Anodizing cannot peel off. The coating is actually part of the metal.

4. Anodizing gives aluminum a deeper, richer metallic appearance than is possible with organic coatings.

This is because an anodized coating is translucent, and one can see the base metal underneath the coating.

This translucence contributes to color variation problems, but anodizers are doing a much better job of controlling the amount of color variation than in the past.

Computerized color matching with quantitative, objective color data is now commonplace in most anodizing facilities.

5. Anodizing is unaffected by sunlight. All organic coatings will eventually fail due to exposure to ultraviolet light.

Good and drawbacks of anodizing

Anodizing that is improperly sealed has poor chemical resistance. Brand new anodizing with a thin coating thickness is nearly identical in appearance to an Aluminum Association Class I (very thick!!) anodized finish, but thin (sub-Class II) anodized coatings are unsuitable for use on exterior curtain walls or metal roofing.

The advantage of a thicker anodic coating is its durability and longer life. The Achilles heel of anodizing is its chemical resistance. Eventually, the surface of an anodic coating may succumb to acidic pollutants in urban environments.

Anodized surfaces, like other building components, must be protected from acidic attacks during construction. The life expectancy of an anodized coating is determined by its thickness and the building’s environment.

After many years anodized surfaces may accumulate dirt and stains that look similar to chalking paint.

This “chalk” can be removed with a mild detergent combined with an abrasive cleaning technique.

A small amount of the anodic coating can actually be removed, leaving behind a renewed anodized finish that can last for another twenty years.

This is why anodizers say their product is “renewable”.

Once an organic coating has failed, the only options are to re-coat the surface with another paint or replace the metal.

When an anodized coating appears to have failed, cleaning often results in a renewed appearance.

Honstar Aluminum Products carries a large inventory of extrusion tooling used in the production of anodizing aluminum profiles and provides a wide variety of finishes for our customers choosing.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote