FAQ about aluminum profile anodizing

FAQ about aluminum profile anodizing

Frequently Asked Questions about anodizing

FAQ about aluminum profile anodizing

What is Anodizing?

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

This electrochemical process provides additional protection aside from the natural oxide film.

A durable, porous anodic oxide layer is formed on the surface of the aluminum. Anodized aluminum will also accept vibrant colors. You can anodize any kind of aluminum alloy.

What is the difference between anodized and mill finished?

Mill finish is the raw state of aluminum as extruded – no surface treatment.

Anodized (also known as Satin Clear or Clear Anodized) is an electrolytic process.

This process increases corrosion resistance and wear resistance.

What determines the thickness of the layer Anodizing?

Determine the layer thickness of the main elements Anodizing is used as the anode current is the amount of aluminum that is given to.

The unit area varies between 1.2 and 2 amps to the current time and the coating thickness of the coating layer is adjusted.

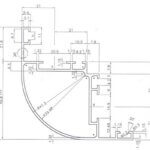

What is aluminum extrusion, fabrication and anodizing?

Aluminum Extrusion refers to a process of creating shapes with an aluminum billet or log by forcing it to flow through a shaped opening in a die.

Aluminum can be extruded into standard shapes or specific designs depending on a customer’s preference.

Aluminum Fabrication refers to building aluminum components by cutting, mitering, notching, piercing, forming, bending, CNC machining, mechanical assembly and welding.

Aluminum anodizing is an electro-chemical process of coating aluminum with a thin layer of oxide to increase corrosion resistance and harden the surface.

Aluminum also can be dyed with various anodizing colors, which in most cases, are resistant to sunlight.

What thickness should Anodizing coating be?

The answer to this question of how much life you get the product you’re willing to be is relevant. 100% recycled aluminum which is a substance used in the financial value of a scrap of aluminum products is high.

Therefore, a certain thickness of the coating will determine the cost of time and use the product’s use is necessary to take into account the environment.

Due to weather conditions, on average, can be assumed Eloxal layer will reduce the annual 0.3 μm.

As an example, lives in Istanbul and the window period of 50 years Anodizing plated and strength you want. Istanbul’s air because of the high-acid ratio of 0:35 to melt in the layer Anodizing as we μm:

0.35 * 50 = 17.5 μm As a result, have received the product you want as Anodizing coating of 18 μm is a correct choice.

The anodizing coating is why?

The anodizing process as decorative and aesthetic purposes, industrial purposes or the use of aluminum against corruption may occur over the surface harder, corrosion-resistant, and long-lasting, apply today to the 1920s.

How to make Color Anodizing?

The dipping method and the electrolytic coloring can be done in two different ways Anodizing color.

The electrolytic coloring method and dipping method, thanks to the advantages are preferred.

The electrolyte as tin sulfate, copper sulfate, cobalt sulfate, and metal salts such as are used.

The electrolytic coloring process to be able to do must be absolutely anodizing.

Anodized aluminum profiles will be offered by Foshan Honstar Aluminum Products Co., Ltd. Extrusion, aging, brushing, polishing and shot blasting, and anodizing will be done under one roof.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote