Aluminum extrusion profile machining and fabrication

Aluminum extrusion profile machining and fabrication

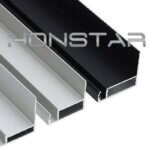

Aluminum extrusion profile processing includes the extrusion process and fabrication and machining process.

Aluminum profile processing plants are generally referred to as aluminum profile extrusion factories,

But some aluminum profile extrusion factories also provide one-stop services such as simple machining, fabrication, CNC machining, prototype building and surface treatment.

Honstar Aluminum Products is such an aluminum profile processing factory.

Aluminum profile extrusion process is to extrude aluminum billets into the required shape through the extrusion machine.

The sizes of aluminum billets used for aluminum profiles with different cross-section sizes are also different, also the extrusion machine capacity is not the same.

The larger the extrusion machine tonnage capacity is, the bigger of aluminum profile cross-section will be.

Our company’s extrusion press ranges from 500 tons to 1800 tons, the maximum size can be 160mm diameter circular section and 140mm * 140mm square section.

Aluminum profiles generally only require corrosion resistance, weather resistance and easy care.

Surface treatment methods are generally anodizing and powder coating.

Anodizing is adding a layer of anodizing film to the surface of the aluminum profile so that the aluminum profile maintains the original aluminum color and is more resistant to corrosion and wear.

Therefore, the most aluminum profile processing plant is equipped with an oxidation treatment workshop and powder coating workshop.

Few aluminum extrusion plants are equipped with deep processing workshops.

Deep processing includes various machining processes, such as sawing, drilling, tapping, milling, turning, riveting, CNC machining and other processes.

More equipment is needed for aluminum extrusion fabrication.

Aluminum extrusion profile machining and fabrication

Honstar Aluminum Products fabrication workshop has CNC machine tools, drilling machines, milling machines, punch press, etc., as well as automatic anodizing production lines and bright dipping anodizing.

After the fabrication and machining, aluminum profiles can generally be directly assembled and used.

One-stop service from aluminum billets to finished aluminum profiles can be offered from Honstar Aluminum Products and it is very popular in the market.

Contact us now for your custom aluminum extrusion and finished aluminum products, one-stop service and total solution!