Why Choose Aluminum Extrusion for Your Project?

Why Choose Aluminum Extrusion for Your Project?

When you’re working on a new architectural project or developing electronic devices, good material selection is always key.

You need materials that are cost-effective, have a high life span and minimize product weight.

But researching different materials can be time-consuming.

The due diligence required for material selection may leave you feeling tired, frustrated and wishing the whole process was easier.

Why Choose Aluminum Extrusion for Your Project?

If you’re considering aluminum extrusion for your project, here are 7 main reasons for it.

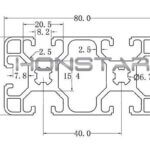

1. Extrudability

Aluminum is truly the metal of modern life. As Aluminum is naturally soft and lightweight. Aluminum can be extruded into a variety of different shapes for different applications.

2. Cost-effective

As Aluminum’s extrudability leads to low tooling costs. Since fewer parts need to be designed, fabrication is reduced and assembly is simplified, so aluminum will be cost-effective for your project.

3. Machining ability

Can be made with different mechanical finishes and different machining works, such as cutting, punching, drilling, notching, bending, milling, tapping, welding, CNC machining, etc, which can meet the project demand.

4. Lightweight

Aluminum has an even higher strength-to-weight ratio than steel, and its weight is only one-third the weight of steel. Not it is a big attribution to the Auto Industry. This makes it easier to handle and less expensive to ship.

5. Surface treatment ability

Aluminum can be made with different surface treatments, such as anodized, powder-coated, Electrophoresis, Wood grain sublimation, bright dipping, hard anodizing, etc. which can easily be applied to further enhance its non-corrosive properties. It can become suitable for even extreme environments.

6. Recyclable

Aluminum retains a high scrap value. It can be recycled indefinitely without losing any of its superior characteristics.

7. Extensive applications

Innovative applications for aluminum are all around us. The car you drive to work most likely has an aluminum hood and other lightweight parts to drive fuel efficiency.

Your house or office building likely uses aluminum windows and doors or maybe even a cool roof to improve insulation and decrease heating and cooling bills.

That airplane you fly in for summer vacation or that latest business trip would literally not be possible without lightweight aluminum as a key component. Increasingly, even the high-tech gadgets you use to keep in touch with friends and family make use of sleek, attractive aluminum casings.

Honstar Aluminum Products is specialized in aluminum extrusion profile manufacturing, fabrication and machining, and also we can advise on aluminum alloy selection, heat treatment procedure and profile design for new product development.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote