Process Improvement for Solar Frame aluminum Profiles to Increase Production Efficiency

Process Improvement for Solar Frame aluminum Profiles to Increase Production Efficiency

The solar frame aluminum profile is the material used to process the solar frame.

The solar frame needs a certain load-bearing capacity, and it must be wind-resistant and corrosion-resistant.

There are two alloy grades for solar frame aluminum profile production in the market: 6063 and 6005.

In the past few years, most of the solar frame aluminum profiles used 6063 alloy, that is, Al-Mg-Si alloy.

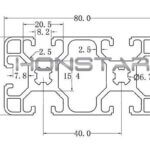

Our common aluminum alloy doors and windows and T slot aluminum profiles are all made of 6063 alloy.

In recent years, due to the increasing size of photovoltaic panels, the 6063 alloy frame can no longer bear large-sized panels, so the aluminum profile of the solar frame also uses 6005 aluminum alloy.

6005 aluminum alloy is also an aluminum-magnesium-silicon alloy, but there are some differences in the alloy composition content.

The silicon content of 6005 is higher than that of 6063, while the content of magnesium is slightly lower than that of 6063.

6005 alloy solar frame aluminum profiles account for the main market share.

|

Mechanical property |

|||||

|

Alloy |

Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation (%) | Hardness

HW |

Temper |

| 6005 | ≥260 | ≥215 | ≥7 | ≥15 | T5 |

| 6063 | ≥160 | ≥110 | ≥8 | ≥10 | T5 |

|

Chemical composition (≤%) |

|||||

| Alloy |

Si |

Fe | Cu |

Mg |

|

| 6005 |

0.60~0.90 |

0.35 | 0.10 |

0.40~0.60 |

|

| 6063 |

0.20~0.60 |

0.35 | 0.10 |

0.45~0.90 |

|

A slight change in the alloy content has a great influence on the mechanical properties of aluminum profile.

Whether it is tensile strength, yield strength or hardness, 6005 is much higher than 6063.

Due to the increase in silicon content, the elongation rate has decreased.

The reduced deformation performance of aluminum alloys increases the difficulty of extrusion of aluminum profiles, therefore, the difficulty of producing 6005 alloy solar frame aluminum profile is slightly greater than that of 6063 alloy aluminum profile.

The following process improvements are made to increase the production of 6005 solar frame aluminum profiles:

Analysis of problems

The main problems in the production process: surface particles, extrusion line, opening size, angle deviation, surface orange peel, welding streak zones, and surface overfiring (Each production unit has different nouns for surface quality defects)

Improvements

First analyze the cause of quality problems, the most important are three factors: aluminum billet composition, mold polishing and mold flow rate, extrusion temperature and extrusion speed control

1. Improvement of aluminum billet composition:

Change the original common composition to homogeneous composition, and homogenize the internal composition (Mg2 si and Fe) of the aluminum billet to improve the surface quality and mechanical properties of solar frame aluminum profiles.

2. Mold Polishing and Mold Flow Rate Improvement:

Mold polishing is a crucial step, and every detail can make a big difference to the mold.

In the initial production of solar frame aluminum profiles, we only used one polishing to send to the extrusion machine for production, and the success rate of the machine was very low.

With the accumulation of experience, the second fine polishing for the mold will be applied before the extrusion, greatly improving the success rate of the mold on the extrusion machine.

The mold of solar frame aluminum profile adopts a double-hole mold, which is changed from a 7-hole porthole flow to a 4-hole porthole flow, which reduces the extrusion pressure, reduces the wear of the working belt of the mold, and prolongs the life of the mold.

3. Extrusion temperature and extrusion speed:

We changed from the original slow extrusion to fast extrusion, and the surface is bound to be overfiring during the rapid extrusion.

The surface adsorption particles will be serious when the extrusion is slow, which completely fails to meet the customer’s quality requirements.

Extrusion temperature “three temperature” improvement

|

Before |

After |

||

| Billet set temperature | 490℃ | Billet set temperature | 530℃ |

| Billet measure temperature | 460-470℃ | Billet measure temperature | 510-520℃ |

| Container | 420℃ | Container | 390℃ |

| Inlet temperature of billet to container | 430-440℃ | Inlet temperature of billet to container | 390-410℃ |

| Outlet temperature | Above 535℃ | Outlet temperature | Above 515°C |

| Load billet quantity | 2 pieces | Load billet quantity | 6-9 pieces |

In the production of solar frame aluminum profile, the process is not fixed, it must be used and changed flexibly.

The devil is in the details.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.