New development of aluminum profile application

New development of aluminum profile application

After years of rapid development, China has become the world’s largest aluminum profile producer and consumer, and its comprehensive strength has been significantly enhanced.

In terms of equipment, China’s heavy tonnage extrusion press, hot rolling, finishing and other equipment have reached the world’s leading level.

Energy-saving and environmentally friendly smelting and casting equipment have been promoted.

The big size of aluminum profile for the transportation industry has made important contributions to China’s high-speed rail becoming a high-end manufacturing business card in China, and positive developments have been made in the development of aluminum for aerospace and automobiles.

According to statistics, there are 113 industries related to aluminum in the existing 124 industries in China.

“replace steel with aluminum profile, save wood with the aluminum profile, save copper with aluminum profile, replace plastic with aluminum profile” have gained broad social consensus.

It can be said that in the whole life cycle of aluminum, due to the abundant reserves of aluminum and excellent performance, aluminum is widely used in industry and life, from aerospace, transportation, and small to household appliances, pots and pans.

Basins have brought enormous social and environmental benefits to many industries and have gained wider recognition.

However, in some emerging application areas, we may need to continue to increase investment in scientific research, change ideas, improve consumption levels, and guide and support mature technologies and related policies to achieve gradual promotion and development.

These include, but are not limited to, traditional consumer applications with significant potential for applications and emerging product applications that have significant social benefits to be promoted.

New development of aluminum profile application

- All-aluminum trailer

If the application ratio of aluminum load trailers in China can reach the level of developed countries, it is expected to increase the consumption of aluminum profiles by more than 7 million tons.

Depending on the type of cargo being transported, 75%-80% of the total number of trailers (about 20%-25% for tank trucks, container trucks and other types of trailers) can be flat-panel or warehouse-style aluminum alloy trailers.

The upper structure of the all-aluminum trailer, such as the trailer body, side protection, rear protection, traction seat plate, suspension, hinge and awning rod, are all made of aluminum alloy material, and the weight of the carriage can be reduced by 3 tons.

The overall vehicle weight is reduced by 3.5 tons compared to the all-steel structure trailer.

This will have great practical significance for promoting energy conservation and emission reduction and transforming the growth mode in China’s transportation sector.

- Aluminum alloy open-top coal truck

Other structures of the aluminum alloy open-top coal car body, such as the chassis and side doors, can be applied with aluminum profile.

At present, 70% of China’s railway freight transport capacity is used for coal transportation.

According to earlier data, the aluminum profile application rate of China’s coal and ore transport rail vehicles is less than 0.5%, which is far from the US’s 28.5%.

- Automobile high-precision aluminum alloy sheet

Whether it is a commercial vehicle or a passenger car, the body is the most expensive part of the car. Among them, the car’s body accounts for about 30% of the vehicle’s mass.

If the four doors and two covers of the car and the fenders are all made of aluminum, the weight can be reduced by about 70 kg.

As China is the world’s largest automobile producer, with the breakthrough of domestic production technology and technology and the successive projects of the project, its application will show rapid growth, and aluminum consumption potential is large.

- Aluminum alloy pallet

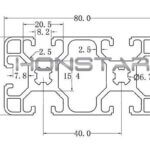

The aluminum alloy pallet mainly adopts 6 series aluminum profiles, its good plasticity and excellent corrosion resistance, especially the tendency of no stress corrosion cracking, and good welding performance, making the 6 series pallet aluminum profiles very suitable for the application of the project.

In order to ensure the quality of the products, advanced welding techniques such as friction stir welding are required to ensure the integral molding of the products.

Aluminum alloy pallet can be applied in the fields of frozen storage, storage of three-dimensional warehouses, pharmaceutical industry, logistics and transportation, food storage, and moisture-proof goods.

According to relevant information, a big tree can only produce up to 6 standard pallets.

Therefore, vigorously promoting the application of aluminum alloy pallets is also of great significance for protecting the ecological environment and conserving natural resources.

- Aluminum alloy flood protection wall

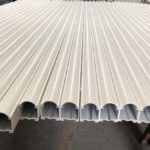

The aluminum alloy flood protection wall is pressed by a 15cm thick aluminum alloy to grow a 2m hollow aluminum beam.

The water-retaining key is to allow water to enter the interior of the aluminum beam to increase the weight of the flood protection baffle.

Such flood protection baffles can generally be used for 50-100 years or even longer.

The assembled flood control wall can be used for dams or river embankments built on concrete foundations, and is easy to install and disassemble.

According to the calculation of 40 kg per square meter of aluminum alloy flood protection wall, the amount of aluminum profile used for the 1 km long and 2 m high flood control wall is about 400 tons.

Although it is not popular, it is worth promoting.

It has significant social benefits in infrastructure construction.

- Aluminum alloy bridge

Aluminum alloy materials have been used in bridge engineering for more than 80 years.

They are relatively mature in foreign countries. As early as 1933, the world’s first aluminum alloy used on bridges was an aluminum alloy bridge across a river bridge in Sfieldfield, Pittsburgh, USA.

For China, the application of aluminum alloy in bridges is still limited, but it has been developing continuously in recent years.

The first bridge of aluminum alloy structure in China is the pedestrian bridge of Qingchun Road in Hangzhou, which was built in 2007. The main material is 6082- T6 aluminum alloy.

China’s aluminum alloy bridges are mainly concentrated on bridges with small load-bearing structures such as pedestrian bridges, and there are also a small number of aluminum alloy panels.

It can be seen that there is still a big gap between the design, manufacture and installation of aluminum alloy bridges.

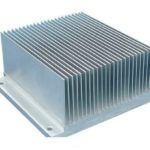

The application of aluminum profiles on bridges, the application of the main structural components includes bridge decks, stringers, trusses and so on.

Among them, the most widely used is the aluminum bridge panel. The auxiliary structural members mainly include: pedestrian or bicycle passage structural members added on the original bridge, bridge railings, road sign brackets, road signs, lighting support rods, etc.

With China’s vigorous development of high-speed rail construction, the terrain in the central and western regions is relatively complex, with numerous canyons and rivers, and a large number of bridges that need to be built during the process of erecting railways.

On the other hand, due to the development of urbanization, the subway is becoming more and more strict with the pressure from the ground.

It can be seen that more aluminum alloy pedestrian bridges and highway bridges will be designed and used in the future.

- Aluminum alloy building formwork

As a new type of building formwork, the aluminum alloy formwork is used for the concrete pouring of the building body, and its appearance conforms to the trend of construction, scale and standardization of the building.

Compared with other traditional building formworks such as wood formwork, steel formwork and plastic formwork, the advantages of aluminum alloy formwork are featured in: repeated use times; low average cost of use; short construction period; safe and tidy construction environment; lightweight and convenient construction, Low carbon emission reduction, saving wood use, etc.

At the same time as domestic aluminum alloy formwork usage continues to increase, domestic companies are also supplying aluminum profiles and aluminum profiles for aluminum alloy formwork and formwork to Brazil, India, Venezuela, Hong Kong and Macao, which will also boost domestic aluminum consumption.

- Aluminum air battery

The aluminum air battery has a high energy density, can achieve zero emission, no pollution during use, and is easy to recycle.

It can be used as a power battery, a signal battery, etc., and has broad application prospects.

- Aluminum alloy cable

Wire and cable products include power cables, electrical equipment cables, winding wires, communication cables, and bare wires.

At present, aluminum and aluminum alloys have been used all over the bare wires in China;

Aluminum and aluminum alloys for electrical equipment are rarely used;

The development trend of communication cables is optical fiber as the transmission conductor; some small electronic transformers in the winding wire are made of aluminum alloy.

As a conductor, but the promotion potential is not great. Therefore, the most popular potential for aluminum in wire and cable is medium and low-voltage power cables.

China’s copper resources are scarce and need to be imported in large quantities.

The use of aluminum resources that have formed a strong industrial base in China, instead of copper resources that are insufficiently guaranteed, can reduce the external dependence of China’s copper resources to a certain extent and enhance the capacity of resources.

- Copper-aluminum composite conductor

The copper-clad aluminum composite conductor is composed of an aluminum core and a copper cladding layer,

And the copper in the middle portion of the conductor is replaced by aluminum, and the influence on the electrical conductivity is compensated by enlarging the cross-sectional area of the conductor, thereby achieving the same electrical conductivity.

Therefore, it has the advantages of excellent electrical conductivity of copper, good corrosion resistance, low cost and light weight of aluminum, and is a kind of high-performance composite conductor.

- All-aluminum furniture

Indoor air pollution caused by construction, decoration and furniture has become an invisible killer for human health.

In the era of personalized and diversified development, home improvement customization is becoming more and more popular.

With the development of technology, all-aluminum furniture is constantly appearing in our field of vision.

It is made of all-aluminum alloy profiles, and the cabinet body and laminate of the wardrobe are all aluminum alloy profiles.

Naturally, it realizes zero formaldehyde, zero pollution, health and environmental protection, beautiful and durable, can be recycled and has super high recycling value.

Even if abandoned, it can still recover 1/3 cost.