How Aluminum Extrusion Enhances Product Design and Functionality

How Aluminum Extrusion Enhances Product Design and Functionality

Aluminum extrusions are made by extruding metal under high pressure until it forms a certain shape.

The finished product can then be used for manufacturing, depending on the needs of the customer.

The extrusion process involves using a high-pressure press that forces a metal billet through an outlet, called a die, which is smaller and/or a differently-shaped cross-section that matches the desired shape of the bar or extruded shape required.

A nearly unlimited number of cross-sections can be produced using the extrusion method.

The resulting aluminum profile can be as long as is necessary but for handling and trucking purposes the standard length is 6 meters long.

In some cases, where small parts are made from the shape, the aluminum profile is cut into shorter lengths.

More than any other metal-forming process, the extrusion process creates various mechanical properties which may be required in the final part being produced.

The process produces an elongated grain structure that increases the raw material’s mechanical strength.

This metal is very easy to work on and holds up well over the years, which is perhaps why it is so popular.

Plus, aluminum extrusions are easily customizable, so you can create them to the exact shape you need to complete your project with ease.

1. Complex and adaptable

The aluminum extrusion process involves 4Cr5MoSiV1 (US temper H13) alloy steel dies that determine the size and shape of the finished shape.

The purpose of the mold is to shape the heated aluminum billet into the desired shape.

There are a variety of options when it comes to the shape and size of your die extrusion to get the results you want.

You can use hollow or solid die in the extrusion process.

Solid dies produce extrusions without any hollow areas.

It is a one-piece simple mold similar to a template.

Hollow molds are shaped with one or more cavities.

It’s more complex than a solid, with two or more openings in a mold that join together to create an inner and outer shape that essentially flow together into a weld as it exits the mold.

Extruded aluminum product development allows for the use of various design features to meet the requirements of the application.

Complex shapes such as groves can be formed, in windows, for example, to improve the design.

Aluminum extrusions offer designers the flexibility to achieve almost any desired design.

The fact that you can create any number of extruded aluminum shapes means the product is highly adaptable and can be used in a variety of different situations.

Before starting your project, you should note that you can buy aluminum extrusions not only in a variety of geometries but also in tubes, flat bars, rod and angle products, etc.

No matter what type of project you’re working on, you can create custom aluminum extrusions in the shape you need to get the job done.

2. Extrudability and cost-effective

Aluminum is truly the metal of modern life.

As Aluminum is naturally soft and lightweight.

Aluminum can be extruded into a variety of different shapes for different applications.

As Aluminum’s extrudability leads to low tooling costs.

Since fewer parts need to be designed, fabrication is reduced and assembly is simplified, so aluminum will be cost-effective for your project.

3. Multiple surface finishes

Due to the naturally occurring oxide film that exists in aluminum and aluminum profiles, these profiles can receive a variety of surface finishes including anodizing, powder coating, fluorocarbon painting, electrophoresis coating, wood grain effect, bright dipping anodizing, brushing, polishing, shot blasting, hammer pinned, etc., which can easily be applied to further enhance its non-corrosive properties.

It can become suitable for even extreme environments.

4. Application in a wide range of industries

Due to the variety of aluminum profile designs, aluminum profile manufacturers offering this service can ensure their customers get what they need.

A wide variety of industries benefit from aluminum extrusion products, including electronics, agriculture, transportation, construction, military and defense, exercise and sports equipment, medical, robotics, and general machinery.

Aluminum profiles are also widely used in the automotive industry.

Because aluminum is both lightweight and strong, it can be used in place of heavier steel or other metals.

Innovative applications for aluminum are all around us.

The car you drive to work most likely has an aluminum hood and other lightweight parts to drive fuel efficiency.

Your house or office building likely uses aluminum windows and doors or maybe even a cool roof to improve insulation and decrease heating and cooling bills.

That airplane you fly in for summer vacation or that latest business trip would literally not be possible without lightweight aluminum as a key component.

Increasingly, even the high-tech gadgets you use to keep in touch with friends and family make use of sleek, attractive aluminum casings.

5. Economic and environmental protection

Those who don’t want to spend too much on building materials may want to talk to an aluminum extrusion supplier, as aluminum can be very affordable, especially when you consider its properties.

Perhaps one of the reasons its price is attractive is that it is the most abundant metal on earth.

Additionally, tooling costs for custom aluminum extrusion can often be recouped through weight and manufacturing savings in a single production run.

Aluminum is also easily recycled, which makes it more environmentally friendly than many other metals.

If you need to replace aluminum extrusions from your job site, you’re sure to find someone willing to recycle it.

6. Longer service life

In general, custom aluminum extrusions last longer than products made of plastic, steel, or other metals.

This is mainly because aluminum is very strong, especially for its weight, and is resistant to corrosion.

You’ll also find that aluminum extrusions can withstand high and low temperatures, which makes them useful in almost any environment.

Those who put their trust in aluminum extrusions are rarely disappointed with the end result, as it is a metal that pays for itself no matter what.

7. Machining ability and Lightweight

Can be made with different mechanical finishes and different machining works, such as cutting, punching, drilling, notching, bending, milling, tapping, welding, CNC machining, etc., which can meet the project demand.

Aluminum has an even higher strength-to-weight ratio than steel, and its weight is only one-third the weight of steel.

Not it is a big attribution to the Auto Industry.

This makes it easier to handle and less expensive to ship.

Aluminum profiles are also widely used in the automotive industry.

Because aluminum is both light and strong, it can be used in place of heavier steel or other metals.

This makes cars, trucks, SUVs and more lighter, more energy efficient to run and less expensive.

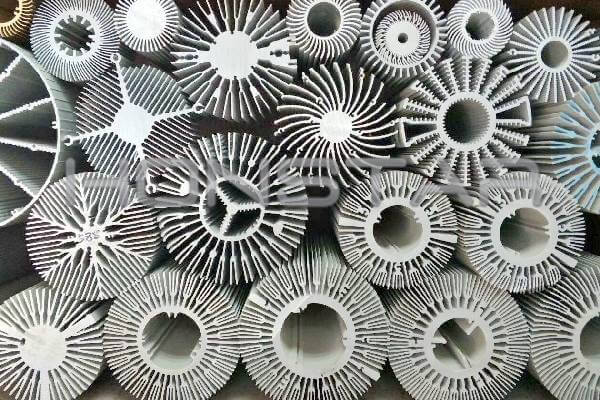

8. Excellent conductor of heat and cold

Extruded aluminum profiles have many advantages over other metals. Aluminum profiles are not only strong and lightweight, but they are also excellent conductors of cold and heat.

Therefore, aluminum extrusions in the shape of heat sinks are a great alternative to using copper to dissipate heat.

From the analysis and comparison, aluminum heat sink is the best choice for heat sink material.

Whether it is energy-saving, materials, decoration, price, weight and other aspects are dominant.

The aluminum heat sink is widely used in the fields of machinery, automobile, wind power generation, construction machinery, air compressor, railway locomotive and household appliance because of its superior performance.

9. Non-magnetic

Apart from all the advantages mentioned above, custom aluminum extrusions are also non-magnetic.

This feature enables its use in high-voltage applications.

This is why these extrusions are widely used by electronics and computer manufacturers.

Additionally, they are spark resistant, which makes them safe for use in applications involving flammable materials.

With so many benefits to using aluminum extrusions, it is important to utilize the best option for your application.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.