Do you offer aluminum extrusion for floor covering profile

Do you offer aluminum extrusion for floor covering profile

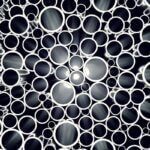

Aluminum extrusion for floor covering profiles

Yes, Honstar Aluminum Products Co., Ltd owns huge existing public molds and also access a full range of floor covering aluminum profiles on behalf of our customers.

In addition to mechanical finishes and chemical finish for floor covering profile, such as brushing, polishing, shot blasting, hammer pinned, wood grain, anodizing, bright dipping, powder coating Etc to make the floor covering profile colorful and smooth.

Floor covering aluminum extrusion is only one small part of what we can do, customized floor covering profiles and end-to-end aluminum floor covering profiles can be provided here, which means that the most of floor covering profiles we supply are made according to our customer’s exact specifications.

Floor covering is a term to generically describe any finish material applied over a floor structure to provide a walking surface.

floor covering refers more to loose-laid materials.

Materials almost always classified as flooring include carpet, laminate, tile, and vinyl. From Wikipedia

Here, floor covering profiles refer to aluminum extrusion profiles for floor covering to protect and match the ceramic, tile, carpet, and laminate, which can be of various shapes and finishes.

Tile trim, carpet trim, transition profile, listello profile, skirting, expansion joint, etc.

Tile trim aluminum profiles will be carried out on an automatic production line consisting of billets heating, extrusion, cooling, straightening, sawing and other processes.

Equipment on the production line, including multi billets heating furnace, extrusion press, run out table, stacker, profile conveyor, cooling bed, tension straightening machine, storage platform, puller, profile sawing machine, etc.

The mechanical finish can be done after the extrusion process, like brushing, polishing, shot blasting, hammer pinned, etc, then the chemical finish will be processed after the mechanical finish, powder coating, anodizing and bright dipping, etc.

We use certificated 6463 alloy ingots for the extrusion and we have our own bright dipping and anodizing workshop with the production license.

Extrusion, polishing and bright dipping anodizing under one roof allows for minimized lead times, reduced production costs, and improved end product quality for our valued customers.

It avoids finger-pointing between subcontractors and the extruder if defects occur, reducing potential customer headaches.

For floor covering aluminum profiles, we offer a full range of extrusion profiles and a one-stop service for your project.

More than aluminum extrusion, profile plus surface, profile plus machining and profile plus service.

Contact us now to get free samples for quality evaluation.

Get Free Samples And Mold List Here