CNC machining service from Honstar

CNC machining service from Honstar

Small and large run jobs both can be accepted, Minimum quantity for an order is only 1 piece.

Short lead times are often available in 2-3 days.

The standard lead time is 10-15 days.

CNC machining service from Honstar

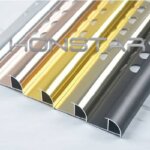

From aluminum extrusion to high-value-added products, we are making progress all the time.

Extrusion, polishing, brushing, sandblasting, anodizing, cutting, and CNC machining work under one roof allows for minimized lead times, reduced production costs, and improved end-product quality for our valued customers.

It avoids finger-pointing between subcontractors and the extruder if defects occur, reducing potential customer headaches.

Aluminum is one of the popular materials due to its excellent mechanical properties. These include affordability, softness, durability, and corrosion resistance.

Aluminum alloys have strong corrosion resistance and corrosion resistance can be excellent because a thin surface layer of aluminum oxide forms when the bare metal is exposed to air, effectively preventing further oxidation in a process termed passivation.

The strongest Aluminium alloys are less corrosion-resistant due to galvanic reactions with alloyed copper.

Aluminum really comes into its own when you combine it with other metals to make aluminum alloys.

A few of the metals commonly used to make aluminum alloys include boron, copper, lithium, magnesium, manganese, silicon, tin, and zinc.

You mix aluminum with one or more of these depending on the job you’re trying to do.

Precision machined aluminum parts are becoming a choice for many industries.

Today, accurately machined aluminum parts are becoming popular in aerospace and military, medical, and industrial engineering.

Special techniques and CNC machines are utilized for aluminum CNC machining because it requires precision. Custom CNC Aluminum Parts

Every element of Honstar Aluminum Products is optimized for CNC aluminum machining success.

From extrusion, cutting, machining, prototype and anodizing, all are traceable and controlled in one house.

Aluminum Machining Benefits

Honstar believes that there are several reasons why companies choose aluminum machined parts over other materials.

In terms of machining materials, aluminum machined parts are the most economical because they can be used in CNC machining and milling for shorter periods of time than other metals.

Aluminum machined products also have added strength, corrosion, and rust resistance due to a protective layer that forms when exposed to the atmosphere.

Furthermore, aluminum machined parts are chemical resistant, electrically conductive, malleable, and possess high strength.

For these reasons and more, Honstar tries to be your first choice in aluminum CNC machining parts!

Working with the following aluminum grades:

The alloy has excellent mechanical properties, such as easy weldability, heat treatability, and durability.

Aluminum 6063 is used for aluminum extrusion applications.

This alloy is commonly used for creating complex shapes with smooth surfaces and is commonly used in applications such as door frames, window frames, sign frames, roofs, etc.

This alloy is a precipitation-hardened aluminum alloy, containing magnesium and silicon as its major alloying elements.

It has good mechanical properties, exhibits good weldability, and is very commonly extruded (second in popularity only to 6063).

It is one of the most common alloys of aluminum for general-purpose use.

Typical properties of aluminum alloy 6061 include Medium to high strength, good toughness, good surface finish during machining, excellent corrosion resistance to atmospheric conditions, good corrosion resistance to seawater, easy to be anodized, good weldability and brazability, and good workability.

Aluminum alloy 6061 is one of the most extensively used in 5-axis precision machining in CNC machine shop industry.

- Aluminum 7075:

This is a popular grade after 6061. Aluminum 7075 is well-known for its excellent fatigue strength.

This grade is not easily weldable and is one of the extremely expensive variants available.

Hence, it is most commonly used for tough components, such as aircraft wings, and fuselages, bicycle components, and rock climbing equipment.

This alloy has better corrosion resistance than the aluminum 2000 alloys. Most times, machine operations are conducted using oil lubricants.

- Aluminum 5052:

It is a non-heat treatable alloy with good corrosion resistance, especially to salt water.

The machinability of Aluminum 5052 alloy is rated as fair.

This alloy can be easily CNC machined in a hard temper than in annealed form, and the quality of finish is better.

Other than in very light cuts, all other machinings should be done using oil lubricants.

More alloys available upon your request

Work piece-tool interaction, when machining aluminum cast alloys results in abrasive flank wear, and influences the shape and the dimensional accuracy as well as the surface integrity of the workpiece.

Cutting forces in the machining of aluminum alloys are usually low compared to those of ferrous alloys due to their lower mechanical strength, which may generate 70 % lower specific cutting pressures than in the machining of steels.

However, it should be noted that this difference is minimal among aluminum alloys and depends on their chemical composition and physical properties

Contact us to ask a question or obtain a reliable no-obligation quote on your custom CNC aluminum parts.