Application and development of aluminum pallet

Application and development of aluminum pallet

The pallet is the carrier of transportation.

It can be used in conjunction with a forklift to effectively replace the labor of manual handling, which greatly saves time and improves efficiency.

The tray can be divided into wooden pallets, plastic pallets and metal pallets according to their materials.

Metal pallets can be divided into stainless steel pallets, steel pallets and aluminum alloy pallets.

With the rapid advancement of the Internet economy, the logistics industry has developed vigorously, demonstrating the important role played by the pallet tool in the development of logistics.

The pallets commonly used earlier were wood and plastic, but in recent years, with the gradual shortage of resources,

Aluminum alloy pallets have gradually emerged based on their many advantages and become the first choice for many logistics industries.

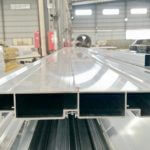

Aluminum alloy pallets are also called aluminum pallets, aluminum table plates, floor plates, aluminum fork plates, aluminum trays, etc.

They are called differently in various regions, but they all reflect their functional characteristics.

The performance characteristics of aluminum alloy pallets are different from wooden pallets, plastic pallets, etc., mainly due to the different selection of their materials.

Aluminum alloy pallets use high-strength aluminum alloys and high-quality raw materials.

The characteristics of aluminum alloys determine that they have the unmatched performance of other pallets.

The aluminum alloy pallet mainly adopts 6 series aluminum profiles,

Its good plasticity and excellent corrosion resistance, especially the tendency of no-stress corrosion cracking, and good welding performance make the 6 series aluminum profiles very suitable for the application of the project.

In order to ensure the quality of the products, advanced welding techniques such as friction stir welding are required to ensure the integral molding of the products.

Aluminum alloy pallets have the following characteristics:

1. Heat resistance, fire and corrosion resistance

The surface of the pallet after anodizing treatment has formed a layer of transparent and hard oxide film, which is not easily damaged in high temperatures or even fire.

It is suitable for many powder industries, humidity, corrosive gases and other special Harsh Environments, long service life, a smooth surface, easy to scrub;

2. The product is light, the structure is firm and safe, and it can be recycled and improved

Aluminum pallets are fireproof, and can prevent flammable and explosive products in many powder industries;

3. Anti-static, anti-magnetic, sterile, low-carbon and environmentally friendly

It can solve the current situation of other trays on the market that are not environmentally friendly, not durable, and unsanitary;

4. As an environmentally friendly material, aluminum is safer to use

Compared with wooden pallets, aluminum pallets are more fire-resistant, anti-corrosive, insect-resistant, and flame-resistant, and have a longer service life;

5. As a metal, it has a stronger load-bearing capacity and is stronger

Because aluminum is light, it is convenient to make light. Quantitative design, free customization, convenient use of finished products, and recycling.

The superior performance of aluminum alloy pallets determines that they are frequently used in various industries such as flat warehouses, cold storage, three-dimensional shelves, supermarkets, food processing, chemical electronics, medicine, logistics food, medicine, chemicals, tobacco, fresh cold chain, and rush logistics, ground storage, shelf storage, cargo intermodal transportation, stacking storage turnover, etc.,

Aluminum alloy pallets, aluminum pallets, aluminum table boards, floorboards, aluminum fork plates, aluminum trays, etc., are used to promote the healthy development of China’s logistics industry and the development of intelligent consignment transportation has a significant impact.

With the development of the combination of the Internet and modern logistics, the requirements and reliance on technical equipment are becoming higher and higher.

Therefore, the logistics auxiliary tools and equipment tend to be cost-effective and have long-term comprehensive benefits.

With these changes, aluminum alloy pallets are still one more efficient and energy-saving equipment tool, which has become an ideal choice for the logistics industry and long-term transportation.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote