Why standard aluminum extrusion for your project

Why standard aluminum extrusion for your project

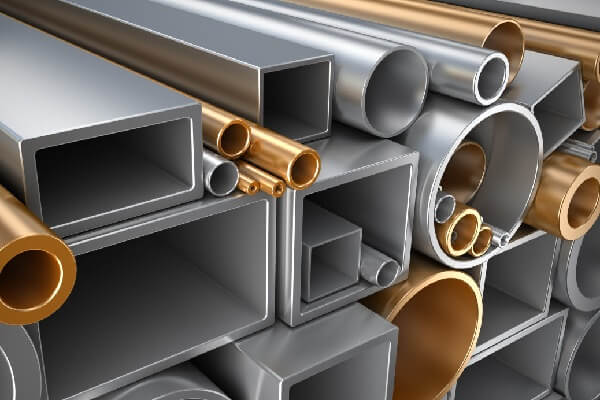

Standard aluminum extrusion, also known as DIY aluminum profiles, involves using pre-existing dies to produce aluminum profiles with standardized shapes and dimensions.

These extrusions are readily available and widely used in various industries due to their cost-effectiveness and versatility.

Standard aluminum extrusions are shapes that are commonly used in a variety of applications.

They are typically produced in large quantities, which makes them more affordable than custom extrusions.

Some common examples of standard aluminum extrusions include:

Tubes: Round, square, and rectangular tubes are used in a wide range of applications, such as structural framing, plumbing, and electrical wiring.

Bars: Solid aluminum bars are used in applications where strength and rigidity are important, such as machine parts and structural components.

Channels: C-shaped channels are used in applications such as framing systems, window tracks, and door guides.

Angles: L-shaped angles are used in applications such as framing systems, brackets, and supports.

Key Characteristics of Standard Aluminum Extrusions:

Readily Available and Cost-Effective: Standard extrusions are produced using standardized dies that are already available, eliminating the need for custom die creation.

This translates to lower production costs and quicker lead times compared to custom aluminum extrusions.

Standard extrusions can typically be shipped much faster than custom extrusions.

Versatile and Widely Used: Standard aluminum extrusions come in a variety of shapes and sizes, including angles, channels, square tubing, and round tubing.

Standard aluminum extrusions are available from a variety of suppliers, which makes it easy to find the right shape and size for your needs.

The variety of standard extrusion shapes makes them suitable for a broad range of applications, from construction and manufacturing to furniture and equipment.

These shapes are also commonly used in various applications, such as framing, structural support, railings, and architectural components.

Consistent Quality and Tolerances: Standard aluminum extrusions are produced using well-established processes and standardized dies, ensuring consistent quality and tight tolerances.

This reliability is crucial for applications where dimensional accuracy is critical.

Advantages of Standard Aluminum Extrusions:

Cost-Effectiveness: Standard extrusions offer a cost-effective solution due to the use of pre-existing dies and the economies of scale associated with mass production.

Cost is a major concern, Standard extrusions are typically more affordable than custom extrusions.

Quick Availability: Standard extrusions are readily available from various suppliers, reducing lead times and simplifying procurement processes.

The desired shape is already available, many common shapes are available as standard extrusions.

Consistent Quality: Standardized production processes and dies ensure consistent material properties and dimensional accuracy.

Ease of Use and Integration: Standard extrusions are well-established and widely used, making them easily integrated into existing designs and manufacturing processes.

Standard aluminum extrusions have been used in a wide range of applications for many years, so their performance is well-established.

Standard aluminum extrusions are typically easy to machine and fabricate, which makes them a good choice for DIYers and professionals alike.

Applications of Standard Aluminum Extrusions:

Construction: Standard aluminum extrusions are widely used in building framing, curtain walls, window frames, doorframes, and railings.

Manufacturing: Standard aluminum extrusions are used in various manufacturing applications, including machinery frames, enclosures, electrical components, and heat sinks.

Furniture: Standard aluminum extrusions are used in furniture frames, table legs, drawer rails, and decorative accents.

Equipment: Standard aluminum extrusions are used in various equipment frames, handles, brackets, and support structures.

Other Applications: Standard aluminum extrusions are also used in a variety of other applications, such as transportation components, lighting fixtures, and signage structures.

Overall, standard aluminum extrusions are a good choice for a wide range of applications.

They are affordable, easy to find, and offer proven performance.

In summary, standard aluminum extrusions offer a cost-effective, versatile, and reliable solution for a wide range of applications.

Their consistent quality, quick availability, and ease of use make them a popular choice for engineers, designers, and manufacturers.