Building formwork aluminum profiles

Building formwork aluminum profiles

Building formwork aluminum profiles

Building formwork aluminum profiles

The aluminum formwork is a building formwork made of aluminum extrusion profile, also known as an aluminum alloy formwork.

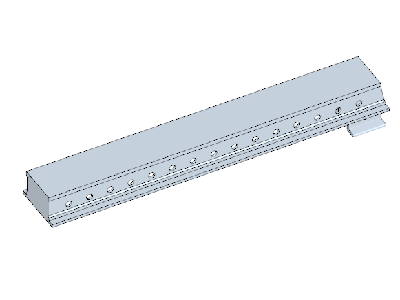

It is a design made of modulus, and the aluminum formwork is made by aluminum extrusion with special equipment.

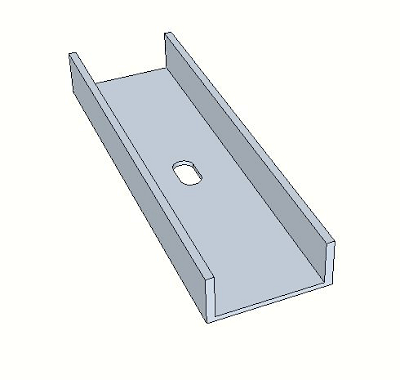

It consists of a three-part system of aluminum panels, brackets and connectors.

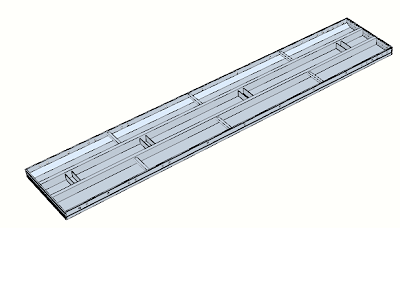

It has a complete set of universal accessories, which can be assembled into different sizes of complex overall mold frames, assembled and industrialized system formwork, which solves the defects of traditional formwork and greatly improves the construction efficiency.

The aluminum formwork is called the aluminum alloy formwork for construction.

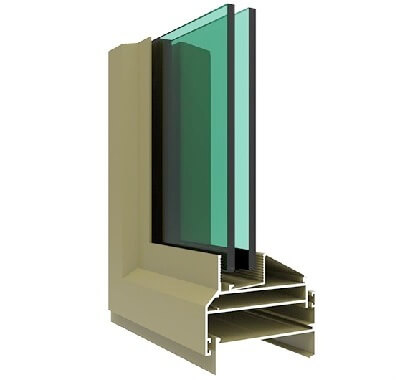

It is a new generation of formwork system that emerged after wood formwork and steel formwork.

Aluminum formwork design and development and construction application is a major development in the construction industry.

As a new type of formwork system, the aluminum alloy formwork quick disassembly system has been used for 50 years since its birth in the United States in 1962. In developed countries such as the United States and Canada, as well as buildings in emerging industrial countries such as Mexico, Brazil, Malaysia, South Korea, and India, they have been widely used in construction.

Aluminum alloy formwork has been developed in China for only a few years and has been favored by many builders.

The aluminum alloy formwork can form a complete system, and can complete the construction of concrete structures such as walls, columns, beams, plates, balconies, bay windows, and exterior decorative lines at one time.

The aluminum alloy formwork system is independent and easy to replace the woodwork and support of the traditional wood formwork. Because the relative density of the aluminum alloy material is 1/3 of the steel, the aluminum alloy formwork is very light, and it is possible to completely transfer the metal without using a tower crane.

Building formwork aluminum profiles advantages

Economical:

Saved about 10% of workers;

Save about 50% of transportation, handling costs, tower crane use costs;

Save about 50% of storage space;

Save 30% of the renovation work hours and materials used in the post-process;

Save about 10% of the construction period;

Save time and costs of cleaning up;

Reuse can be up to 300 times, with a lower average cost of use;

The residual value recovery rate is over 30%.

Environmental protection:

The formwork can be reused for about 300 times ;

Almost no garbage is generated during the installation and removal process;

Hard nails and other consumables are hardly used during installation;

The residual value is completely recovered, and the recovery rate is over 30%, which is green and environmentally friendly;

Replacing traditional wooden formwork to reduce deforestation;

It meets the development requirements of China’s green environmental protection and energy conservation.

Aluminum formwork profiles have become increasingly popular in construction for several reasons compared to traditional wood or steel formwork:

Efficiency and Speed: Due to their lightweight nature and modular design, aluminum formwork systems can be assembled and disassembled much faster than traditional options. This interlocking system often eliminates the need for complex support structures, further streamlining the process and saving time on projects.

Cost-Effectiveness: While there might be a higher upfront cost for the aluminum system itself, reusability is a major advantage. Aluminum profiles can be used for hundreds of pours without warping or degrading significantly, unlike wood. This reusability brings down the overall project cost per use compared to needing to purchase new wooden formwork for each concrete pour.

High-Quality Finish: Aluminum is dimensionally stable and less prone to warping than wood. This translates to a smoother and more consistent concrete finish, potentially reducing the need for additional labor and materials required for extensive post-pour touch-up work.

Reduced Labor: The lightweight nature of aluminum formwork makes it easier to handle and maneuver on the job site. This reduces the strain on workers and potentially lowers labor costs associated with traditional heavier formwork materials.

Sustainable Choice: Aluminum is a recyclable material. When a project is complete, the aluminum formwork can be recycled and used again in future construction projects, minimizing environmental impact.

Safer Work Environment: The lighter weight of aluminum formwork reduces the risk of worker injuries during handling and installation compared to heavier steel components.