How are tile trim aluminum profiles produced?

How are tile trim aluminum profiles produced?

Tile trim aluminum profiles are useful metal trim to protect the edges of your tiles and also support and protect them.

Tile trim aluminum profiles product safeguard the tiles from chipping or cracking at the edges due to pressure.

Also, tile trim aluminum profiles products are used to prevent intense pressure from breaking the tile, especially at the dividers between ceramic tiles and the walls.

The tile trim also helps to provide an aesthetic look to the tiled floor bottom. They could be straight or round and are made of high-quality materials.

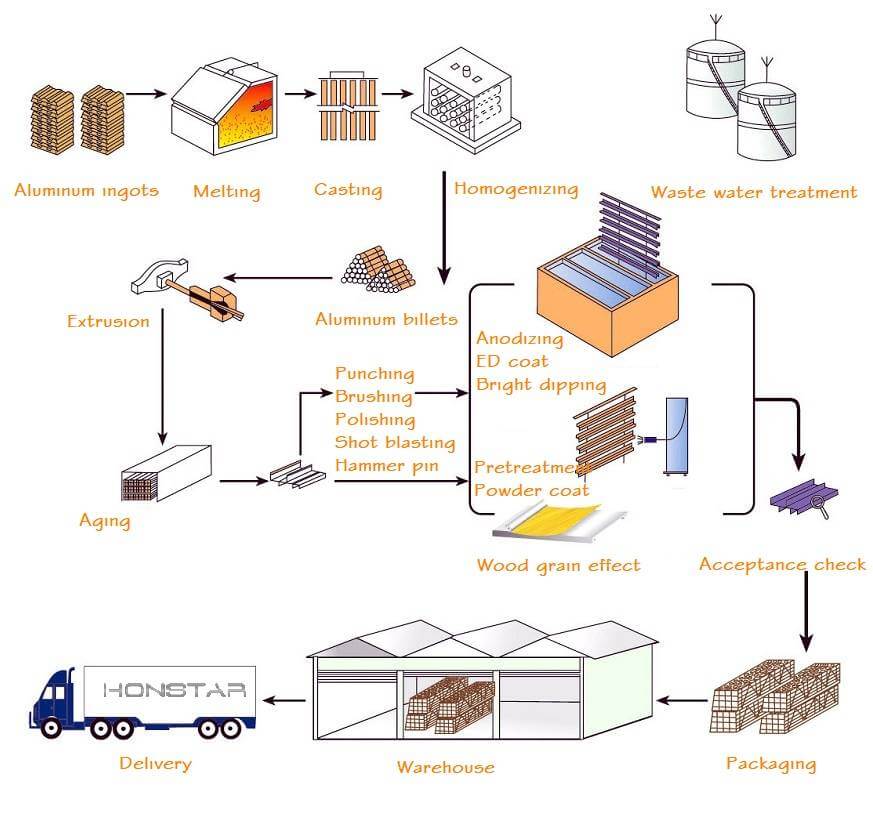

You may wonder what process make tile trim aluminum profiles in production.

Die process, the first step of tile trim aluminum profiles detailed production process

Die process, tile trim aluminum profiles production

Here is the details information for the die process:

Die design:

Tile trim aluminum profiles are the final product of aluminum billets that are extruded through a die after heating, and the extrusion die is a device with high-precision specifications designed according to demand to extrude aluminum profiles with the required specifications and cross-sections;

The design of the die and maintenance should pay attention to the followings:

1. The structure involved in the die must first meet the production requirements and also meet the common knowledge of physical mechanics to ensure that tile trim aluminum profiles produced can reach the performance used.

2. The material selection and hardness of the die should be appropriate to avoid deformation, scratches and other hard injuries during the extrusion process, which will affect the quality of tile trim aluminum profiles

3. The extrusion die should be cleaned and inspected frequently.

If there are any problems, they should be repaired in time to avoid scratches, burrs and other hard injuries during the extrusion process of the profile, which will seriously affect the quality of tile trim aluminum profiles.

Extrusion die processing process flow chart

Solid die (structural profile without a closed cavity, not the porthole die)

Lathing → Scribing → Milling → Drilling → Grinding → Hardening → Tempering → Grinding of the surface → Fine milling of the guide channel → Wire cutting → EDM → Polishing → Clamping repairing → Acceptance → Test mold → Nitriding → Warehouse

Since the extrusion die is the basic for tile trim aluminum profiles and we have the possibility for the tile trim shape we required through the extrusion process.

Melting process, tile trim aluminum profiles production second step

Aluminum billets, tile trim aluminum profiles production raw materials

1. Alloys and their application

6063 and 6463 are common alloys for tile trim aluminum profiles production.

In general, 6063 alloy is main for mill finish, matt silver, matt gold, matt bronze, matt black and powder coated color tile trim aluminum profiles production.

6463 aluminum alloy is an alloy in the wrought aluminum-magnesium-silicon family (6000 or 6xxx series).

It is related to 6063 aluminum alloy (Aluminum Association designations that only differ in the second digit are variations on the same alloy), but unlike 6063 it is generally not formed using any processes other than extrusion.

It cannot be work-hardened but is commonly heat-treated to produce tempers with a higher strength but lower ductility.

Like 6063, it is often used in architectural applications.

6463 alloy is for shiny colors, like bright silver, bright gold, bright bronze, bright black and brushed stainless steel color tile trim aluminum profiles production.

Mechanical polishing plus chemical polishing (Bright dipping and anodizing) with 6463 alloy, can get a mirror-like effect on tile trim aluminum products.

|

Chemical composition |

|||||||||

|

ITEM |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

|

6063 |

0.20~0.60 |

≤0.35 |

≤0.10 |

≤0.10 |

0.45~0.90 |

≤0.10 |

≤0.15 |

≤0.10 |

Remainder |

|

6463 |

0.20~0.60 |

≤0.15 |

≤0.20 |

≤0.05 |

0.45~0.90 |

≤0.05 |

≤0.05 |

Remainder |

|

2. Melting processing flow chart

Materials→charging→melting→stirring→alloying→holding→degassing→refining→log casting→homogenizing→cutting

Now we get the aluminum billets for the extrusion, tile trim aluminum profiles mold and aluminum billets are ready and we will get tile trim aluminum profiles through the extrusion process.

Extrusion process, tile trim aluminum profiles production third step

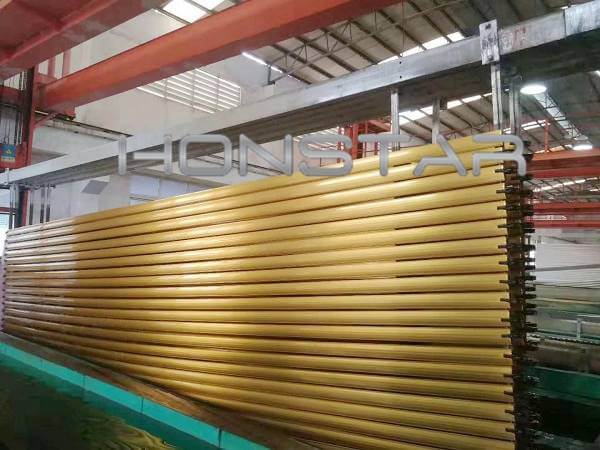

Tile trim aluminum profiles production extrusion process

Extrusion process

Aluminum extrusion is one process by which aluminum is forced into a custom-made die and results in a constant cross-section that utilizes all the properties of the metal.

As tile trim molds were designed and aluminum billets are available in the first step and second steps.

All is ready for tile trim extrusion.

Tile trim aluminum profiles will be carried out on an automatic production line consisting of billets heating, extrusion, cooling, tension straightening, sawing and other processes.

Equipment on the production line, including multi billets heating furnace, extrusion press, run-out table, stacker, profile conveyor, cooling bed, tension straightening machine, storage platform, puller, profile sawing machine, etc.

The billet heating temperature is generally controlled at 400 ° C ~ 520 ° C, too high or too low a temperature will directly affect the aluminum tile trim shape.

The working temperature of the extrusion tool is 360 ° C ~ 460 ° C, and the extrusion speed is 20 m / min ~ 80 m / min.

After tile trim aluminum extrusion is done, will be sawed in the extrusion line.

As it is soft and we need to make them aging for the hardness in the aging furnace.

Now tile trim aluminum profiles will be got and it is only mill finished tile trim aluminum profiles.

It is only the start, we need to make them punched, mechanical process and chemical process to get different finishes to match the project.

We will see what happens in the next process.

Surface treatment process, tile trim aluminum profiles production fourth step

Surface treatment: Mechanical treatment plus chemical treatment

Surface treatment

Tile trim aluminum profiles were got in the extrusion process.

As it is a mill finish profile, without any surface treatment, only bare aluminum.

We need to make it surface treated for different finishes to meet the different materials and project demands.

There are 2 kinds of popular surface treatment in this process

1. Mechanical finish

Mechanical finish methods can give tile trim aluminum profiles several different types of surface texture – from rough or patterned to a mirror finish.

Polishing, brushing, sandblasting or shot blasting, grinding, and hammer pinned, all belong to mechanical finishes and that will make tile trim aluminum profiles more pattern and texture.

Tile trim aluminum profiles need to be anodized or bright dipping and anodized after mechanical finishes.

2. Chemical finish

The chemical finish method can give tile trim aluminum profiles corrosion-resistant, wear-resistant and weather resistance ability with the anodizing film or powder-coated layer.

Anodizing process, powder coating process, woodgrain effect or marble effect plus powder coating, bright dipping anodizing, and ED coating belong to chemical finishes and that will make tile trim aluminum profiles colorful and elegant.

Through chemical finishes, Matt silver, Matt bronze, Matt gold, Matt black, Matt champagne, RAL powder coated colors, brushing shiny color, Shiny silver, Shiny gold, Shiny bronze, shiny black, woodgrain effect, marble effect, hammer pinned, brass color, etc tile trim aluminum products can be got.

Now tile trim aluminum profiles are done and we need to cut the jig mark, QC will inspect the quality one by one prior to the packaging.

The production is not finished and the next process is the important part for our customers.

We will see the next process to make the packaging for different shapes and surfaces.

In Honstar Aluminum Products, we knew the story behind the production and we also know your request well for tile trim aluminum profiles.

From tile trim aluminum profiles to packaging and delivery, all processes will be handled carefully to ensure the products you received are in perfect condition after you open the package.

Packaging process, tile trim aluminum profiles production fifth step

Tile trim aluminum profiles packaging process

The packaging process for tile trim aluminum profiles

Now finished tile trim aluminum profiles are done in the surface treatment process and the jig mark needs to be cut for precise length.

Then we will move to the next process for tile trim aluminum profiles packaging.

Tile trim aluminum profiles packaging function is to protect tile trim product in the transportation, ensure the customers receive the product in perfect condition.

The flexibility of custom packaging styles to meet different demands is what we are doing and looking for.

Good and proper packaging can protect tile trim aluminum profiles to avoid damage and scratch in transportation.

The packaging way for tile trim aluminum profiles will be varied according to the local market or overseas market sales, tile trim shape and size and surface, what kind of packaging materials, what kind of packaging machine application, and loading and unloading way.

All packaging work is to make sure each piece of tile trim aluminum profile you received is a high-quality product ready for use after you open the packages of aluminum tile trim products from us.

No matter what shape or size, tile trim aluminum profile has a package design that will meet your needs, and get to your place in good condition.

For tile trim aluminum profiles packaging, the basic idea is to provide optimum protection while minimizing packaging materials and waste.

Now the packaging work is done and we can deliver tile trim aluminum profiles to our customers.

The whole process is done and now it is time to see how the tile trim aluminum products turn the tile into an incredible interior design world!

Honstar Aluminum Products offers a total solution for floor covering aluminum profiles, contact us now to get a reliable no-obligation quote on your aluminum tile trim products!