7 benefits of hard coat anodizing application

7 benefits of hard coat anodizing application

Hard coat anodizing application 7 benefits

Hard coat anodizing application benefits as follows:

1. It can be colored with a hard coat anodizing;

2. Hard coat anodizing of die-casting aluminum alloy:

The thickness of the typical material ADC12 can reach more than 25um, and the other can reach more than 35um.

3. Can work for difficult workpieces such as 2xxx 7xxx aluminum alloy.

4. Composite hard coat anodizing applied in the field of high insulation:

The patented product “aluminum nitride composite hard coat anodizing” was successfully used in high heat dissipation LED heat dissipation aluminum substrates, and successfully replaced aluminum-based copper clad.

5. Self-lubricating closed (Teflon) composite hard coat anodizing.

6. Hard coat anodizing of components:

Such as control valves, printing machines, motorcycle parts, auto parts, fluid hydraulic components, textile machines, air compressors, sewing machines, precision numerical control, tooling and molds, pneumatic components, household kitchenware, and aviation joints.

7. Mixed acid type hard oxidation:

The toughness is improved, and the condition of hard coat anodizing cracking is significantly reduced.

In hard coat anodizing, the anodizing film of pure aluminum, aluminum-magnesium alloy and the aluminum-manganese alloy is easy to be dyed in various colors.

The anodizing film of aluminum-copper and aluminum-silicon alloy is dark and can only be dyed dark.

The fresh oxide film obtained after anodizing can be colored in time, which not only beautifies the surface of the oxide film but also increases the corrosion resistance.

The thickness of the anodizing film can be up to about 250 microns.

The microhardness anodizing film of 1500kg / mm2 can be obtained on pure aluminum, and the microhardness anodizing film of 400-600kg / mm2 can be obtained on aluminum alloy.

Its hardness value, the inner layer of the oxide film is larger than the outer layer,

That is, the barrier layer is larger than the oxide film layer with pores,

Because the oxide film has loose pores, it can absorb various lubricants, increasing the friction reducing ability,

And the oxide film layer has poor thermal conductivity,

Its melting point is 2050 ℃,

The resistance coefficient is large,

The breakdown voltage can reach 2000V after sealing treatment (dip insulation or paraffin), high corrosion resistance in the atmosphere, and high wear resistance.

It is also a kind of ideal thermal insulation film layer, also has good insulation, and has a series of advantages such as strong bonding with the base metal.

7 benefits of hard coat anodizing application

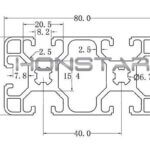

Foshan Honstar Aluminum Products Co., Ltd provides standard anodizing aluminum profile and hard coat anodizing aluminum parts for our customers, not only aluminum extrusion profile, but also finished products and one-stop service.

Contact us now to obtain a reliable no-obligation quote on your hard coating anodizing aluminum profiles demand.